Page 283 - The Jet Engine

P. 283

Overhaul

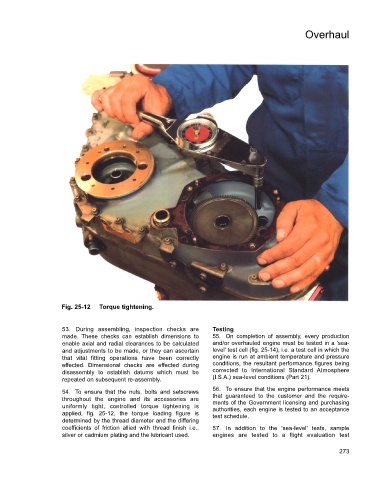

Fig. 25-12 Torque tightening.

53. During assembling, inspection checks are Testing

made. These checks can establish dimensions to 55. On completion of assembly, every production

enable axial and radial clearances to be calculated and/or overhauled engine must be tested in a 'sea-

and adjustments to be made, or they can ascertain level' test cell (fig. 25-14), i.e. a test cell in which the

that vital fitting operations have been correctly engine is run at ambient temperature and pressure

effected. Dimensional checks are effected during conditions, the resultant performance figures being

disassembly to establish datums which must be corrected to International Standard Atmosphere

repeated on subsequent re-assernbly. (I.S.A.) sea-level conditions (Part 21).

56. To ensure that the engine performance meets

54. To ensure that the nuts, bolts and setscrews

throughout the engine and its accessories are that guaranteed to the customer and the require-

ments of the Government licensing and purchasing

uniformly tight, controlled torque tightening is authorities, each engine is tested to an acceptance

applied, fig. 25-12, the torque loading figure is test schedule.

determined by the thread diameter and the differing

coefficients of friction allied with thread finish i.e., 57. In addition to the 'sea-level' tests, sample

silver or cadmium plating and the lubricant used. engines are tested to a flight evaluation test

273