Page 279 - The Jet Engine

P. 279

Overhaul

Balancing

40. Because of the high rotational speeds, any

unbalance in the main rotating assembly of a gas

turbine engine is capable of producing vibration and

stresses which increase as the square of the

rotational speed. Therefore very accurate balancing

of the rotating assembly is necessary.

41. The two main methods of measuring and

correcting unbalance are single plane (static)

balancing and two plane (dynamic) balancing. With

single plane, the unbalance is only in one plane i.e.,

centrally through the component at 90 degrees to the

axis. This is appropriate for components such as

individual compressor or turbine discs.

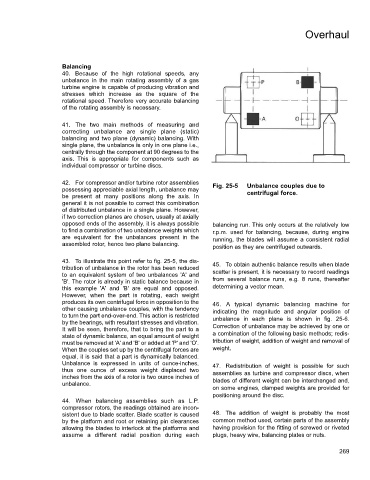

42. For compressor and/or turbine rotor assemblies Fig. 25-5 Unbalance couples due to

possessing appreciable axial length, unbalance may

be present at many positions along the axis. In centrifugal force.

general it is not possible to correct this combination

of distributed unbalance in a single plane. However,

if two correction planes are chosen, usually at axially

opposed ends of the assembly, it is always possible balancing run. This only occurs at the relatively low

to find a combination of two unbalance weights which r.p.m. used for balancing, because, during engine

are equivalent for the unbalances present in the running, the blades will assume a consistent radial

assembled rotor, hence two plane balancing.

position as they are centrifuged outwards.

43. To illustrate this point refer to fig. 25-5, the dis- 45. To obtain authentic balance results when blade

tribution of unbalance in the rotor has been reduced

to an equivalent system of two unbalances 'A' and scatter is present, it is necessary to record readings

'B'. The rotor is already in static balance because in from several balance runs, e.g. 8 runs, thereafter

this example 'A' and 'B' are equal and opposed. determining a vector mean.

However, when the part is rotating, each weight

produces its own centrifugal force in opposition to the 46. A typical dynamic balancing machine for

other causing unbalance couples, with the tendency indicating the magnitude and angular position of

to turn the part end-over-end. This action is restricted

by the bearings, with resultant stresses and vibration. unbalance in each plane is shown in fig. 25-6.

It will be seen, therefore, that to bring the part to a Correction of unbalance may be achieved by one or

state of dynamic balance, an equal amount of weight a combination of the following basic methods; redis-

must be removed at 'A' and 'B' or added at 'P' and 'O'. tribution of weight, addition of weight and removal of

When the couples set up by the centrifugal forces are weight.

equal, it is said that a part is dynamically balanced.

Unbalance is expressed in units of ounce-inches, 47. Redistribution of weight is possible for such

thus one ounce of excess weight displaced two assemblies as turbine and compressor discs, when

inches from the axis of a rotor is two ounce inches of blades of different weight can be interchanged and,

unbalance.

on some engines, clamped weights are provided for

positioning around the disc.

44. When balancing assemblies such as L.P.

compressor rotors, the readings obtained are incon-

sistent due to blade scatter. Blade scatter is caused 48. The addition of weight is probably the most

by the platform and root or retaining pin clearances common method used, certain parts of the assembly

allowing the blades to interlock at the platforms and having provision for the fitting of screwed or riveted

assume a different radial position during each plugs, heavy wire, balancing plates or nuts.

269