Page 48 - The Jet Engine

P. 48

Combustion chambers

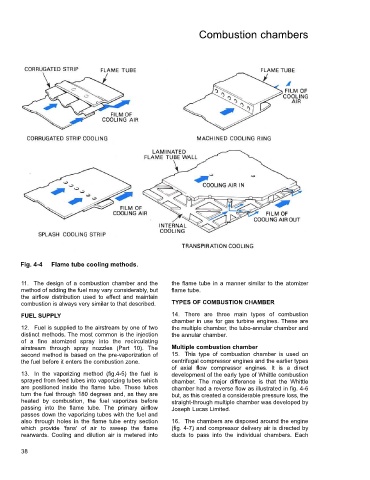

Fig. 4-4 Flame tube cooling methods.

11. The design of a combustion chamber and the the flame tube in a manner similar to the atomizer

method of adding the fuel may vary considerably, but flame tube.

the airflow distribution used to effect and maintain

combustion is always very similar to that described. TYPES OF COMBUSTION CHAMBER

FUEL SUPPLY 14. There are three main types of combustion

chamber in use for gas turbine engines. These are

12. Fuel is supplied to the airstream by one of two the multiple chamber, the tubo-annular chamber and

distinct methods. The most common is the injection the annular chamber.

of a fine atomized spray into the recirculating

airstream through spray nozzles (Part 10). The Multiple combustion chamber

second method is based on the pre-vaporization of 15. This type of combustion chamber is used on

the fuel before it enters the combustion zone. centrifugal compressor engines and the earlier types

of axial flow compressor engines. It is a direct

13. In the vaporizing method (fig.4-5) the fuel is development of the early type of Whittle combustion

sprayed from feed tubes into vaporizing tubes which chamber. The major difference is that the Whittle

are positioned inside the flame tube. These tubes chamber had a reverse flow as illustrated in fig. 4-6

turn the fuel through 180 degrees and, as they are but, as this created a considerable pressure loss, the

heated by combustion, the fuel vaporizes before straight-through multiple chamber was developed by

passing into the flame tube. The primary airflow Joseph Lucas Limited.

passes down the vaporizing tubes with the fuel and

also through holes in the flame tube entry section 16. The chambers are disposed around the engine

which provide 'fans' of air to sweep the flame (fig. 4-7) and compressor delivery air is directed by

rearwards. Cooling and dilution air is metered into ducts to pass into the individual chambers. Each

38