Page 71 - The Jet Engine

P. 71

Exhaust system

EXHAUST GAS FLOW

4. Gas from the engine turbine enters the exhaust

system at velocities from 750 to 1,200 feet per

second, but, because velocities of this order produce

high friction losses, the speed of flow is decreased by

diffusion. This is accomplished by having an

increasing passage area between the exhaust cone

and the outer wall as shown in fig. 6-1. The cone also

prevents the exhaust gases from flowing across the

rear face of the turbine disc. It is usual to hold the

velocity at the exhaust unit outlet to a Mach number

of about 0.5, i.e. approximately 950 feet per second.

Additional losses occur due to the residual whirl

velocity in the gas stream from the turbine. To reduce

these losses, the turbine rear struts in the exhaust

unit are designed to straighten out the flow before the

gases pass into the jet pipe.

5. The exhaust gases pass to atmosphere through

the propelling nozzle, which is a convergent duct,

thus increasing the gas velocity (Part 2). In a turbo-

jet engine, the exit velocity of the exhaust gases is

subsonic at low thrust conditions only. During most

operating conditions, the exit velocity reaches the

speed of sound in relation to the exhaust gas

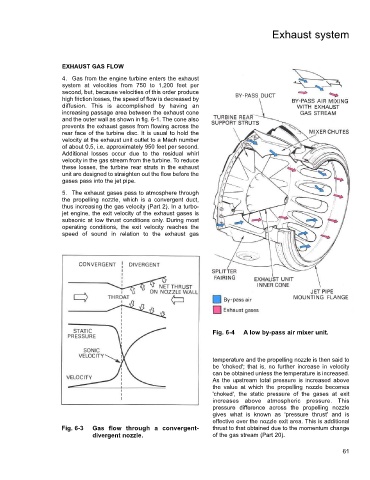

Fig. 6-4 A low by-pass air mixer unit.

temperature and the propelling nozzle is then said to

be 'choked'; that is, no further increase in velocity

can be obtained unless the temperature is increased.

As the upstream total pressure is increased above

the value at which the propelling nozzle becomes

'choked', the static pressure of the gases at exit

increases above atmospheric pressure. This

pressure difference across the propelling nozzle

gives what is known as 'pressure thrust' and is

effective over the nozzle exit area. This is additional

Fig. 6-3 Gas flow through a convergent- thrust to that obtained due to the momentum change

divergent nozzle. of the gas stream (Part 20).

61