Page 77 - The Jet Engine

P. 77

Accessory drives

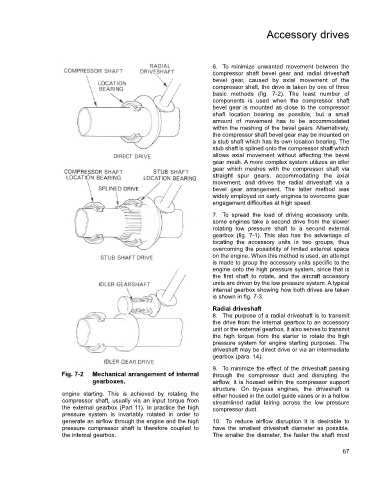

6. To minimize unwanted movement between the

compressor shaft bevel gear and radial driveshaft

bevel gear, caused by axial movement of the

compressor shaft, the drive is taken by one of three

basic methods (fig. 7-2). The least number of

components is used when the compressor shaft

bevel gear is mounted as close to the compressor

shaft location bearing as possible, but a small

amount of movement has to be accommodated

within the meshing of the bevel gears. Alternatively,

the compressor shaft bevel gear may be mounted on

a stub shaft which has its own location bearing. The

stub shaft is splined onto the compressor shaft which

allows axial movement without affecting the bevel

gear mesh. A more complex system utilizes an idler

gear which meshes with the compressor shaft via

straight spur gears, accommodating the axial

movement, and drives the radial driveshaft via a

bevel gear arrangement. The latter method was

widely employed on early engines to overcome gear

engagement difficulties at high speed.

7. To spread the load of driving accessory units,

some engines take a second drive from the slower

rotating low pressure shaft to a second external

gearbox (fig. 7-1). This also has the advantage of

locating the accessory units in two groups, thus

overcoming the possibility of limited external space

on the engine. When this method is used, an attempt

is made to group the accessory units specific to the

engine onto the high pressure system, since that is

the first shaft to rotate, and the aircraft accessory

units are driven by the low pressure system. A typical

internal gearbox showing how both drives are taken

is shown in fig. 7-3.

Radial driveshaft

8. The purpose of a radial driveshaft is to transmit

the drive from the internal gearbox to an accessory

unit or the external gearbox. It also serves to transmit

the high torque from the starter to rotate the high

pressure system for engine starting purposes. The

driveshaft may be direct drive or via an intermediate

gearbox (para. 14).

9. To minimize the effect of the driveshaft passing

Fig. 7-2 Mechanical arrangement of internal through the compressor duct and disrupting the

gearboxes. airflow, it is housed within the compressor support

structure. On by-pass engines, the driveshaft is

engine starting. This is achieved by rotating the either housed in the outlet guide vanes or in a hollow

compressor shaft, usually via an input torque from streamlined radial fairing across the low pressure

the external gearbox (Part 11). In practice the high compressor duct.

pressure system is invariably rotated in order to

generate an airflow through the engine and the high 10. To reduce airflow disruption it is desirable to

pressure compressor shaft is therefore coupled to have the smallest driveshaft diameter as possible.

the internal gearbox. The smaller the diameter, the faster the shaft must

67