Page 89 - The Jet Engine

P. 89

Lubrication

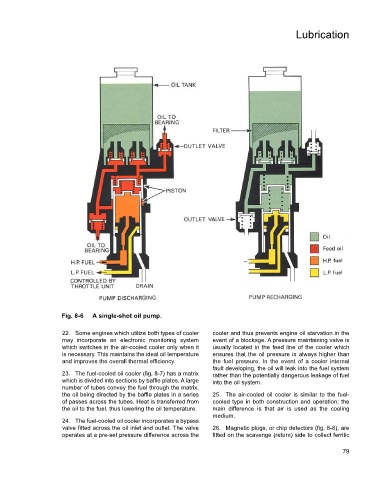

Fig. 8-6 A single-shot oil pump.

22. Some engines which utilize both types of cooler cooler and thus prevents engine oil starvation in the

may incorporate an electronic monitoring system event of a blockage. A pressure maintaining valve is

which switches in the air-cooled cooler only when it usually located in the feed line of the cooler which

is necessary. This maintains the ideal oil temperature ensures that the oil pressure is always higher than

and improves the overall thermal efficiency. the fuel pressure. In the event of a cooler internal

fault developing, the oil will leak into the fuel system

23. The fuel-cooled oil cooler (fig. 8-7) has a matrix rather than the potentially dangerous leakage of fuel

which is divided into sections by baffle plates. A large into the oil system.

number of tubes convey the fuel through the matrix,

the oil being directed by the baffle plates in a series 25. The air-cooled oil cooler is similar to the fuel-

of passes across the tubes. Heat is transferred from cooled type in both construction and operation; the

the oil to the fuel, thus lowering the oil temperature. main difference is that air is used as the cooling

medium.

24. The fuel-cooled oil cooler incorporates a bypass

valve fitted across the oil inlet and outlet. The valve 26. Magnetic plugs, or chip detectors (fig. 8-8), are

operates at a pre-set pressure difference across the fitted on the scavenge (return) side to collect ferritic

79