Page 91 - The Jet Engine

P. 91

Lubrication

debris from each bearing chamber. They are

basically permanent magnets inserted in the oil flow

and are retained in self-sealing valve housings.

Safety features incorporated in the design ensure

correct retention within the housing. Upon

examination they can provide a warning of

impending failure without having to remove and

inspect the filters. They are designed to be removed

during maintenance inspection, for condition,

monitoring purposes (Part 24), without oil loss

occurring. Additionally they may be connected to a

cockpit warning system to give an in-flight indication.

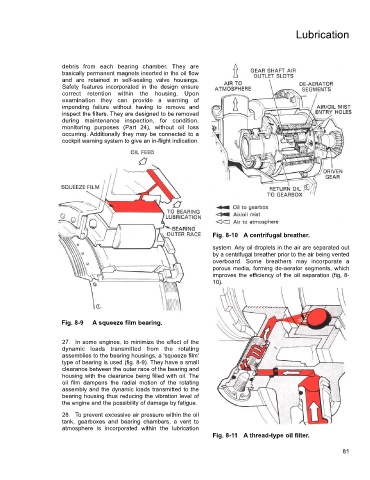

Fig. 8-10 A centrifugal breather.

system. Any oil droplets in the air are separated out

by a centrifugal breather prior to the air being vented

overboard. Some breathers may incorporate a

porous media, forming de-aerator segments, which

improves the efficiency of the oil separation (fig, 8-

10).

Fig. 8-9 A squeeze film bearing.

27. In some engines, to minimize the effect of the

dynamic loads transmitted from the rotating

assemblies to the bearing housings, a 'squeeze film'

type of bearing is used (fig. 8-9). They have a small

clearance between the outer race of the bearing and

housing with the clearance being filled with oil. The

oil film dampens the radial motion of the rotating

assembly and the dynamic loads transmitted to the

bearing housing thus reducing the vibration level of

the engine and the possibility of damage by fatigue.

28. To prevent excessive air pressure within the oil

tank, gearboxes and bearing chambers, a vent to

atmosphere is incorporated within the lubrication

Fig. 8-11 A thread-type oil filter.

81