Page 96 - The Jet Engine

P. 96

Internal air system

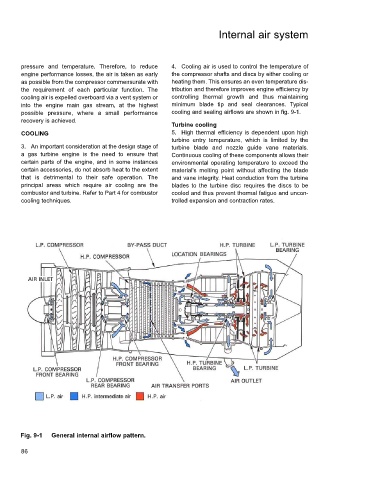

pressure and temperature. Therefore, to reduce 4. Cooling air is used to control the temperature of

engine performance losses, the air is taken as early the compressor shafts and discs by either cooling or

as possible from the compressor commensurate with heating them. This ensures an even temperature dis-

the requirement of each particular function. The tribution and therefore improves engine efficiency by

cooling air is expelled overboard via a vent system or controlling thermal growth and thus maintaining

into the engine main gas stream, at the highest minimum blade tip and seal clearances. Typical

possible pressure, where a small performance cooling and sealing airflows are shown in fig. 9-1.

recovery is achieved.

Turbine cooling

COOLING 5. High thermal efficiency is dependent upon high

turbine entry temperature, which is limited by the

3. An important consideration at the design stage of turbine blade and nozzle guide vane materials.

a gas turbine engine is the need to ensure that Continuous cooling of these components allows their

certain parts of the engine, and in some instances environmental operating temperature to exceed the

certain accessories, do not absorb heat to the extent material's melting point without affecting the blade

that is detrimental to their safe operation. The and vane integrity. Heat conduction from the turbine

principal areas which require air cooling are the blades to the turbine disc requires the discs to be

combustor and turbine. Refer to Part 4 for combustor cooled and thus prevent thermal fatigue and uncon-

cooling techniques. trolled expansion and contraction rates.

Fig. 9-1 General internal airflow pattern.

86