Page 99 - The Jet Engine

P. 99

Internal air system

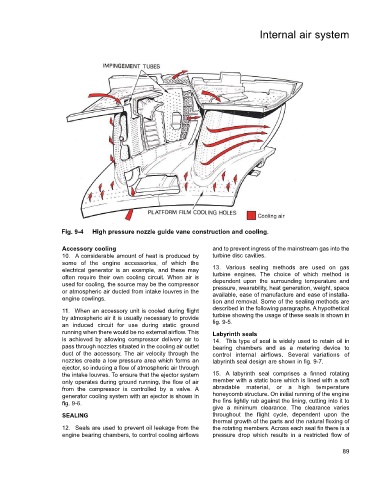

Fig. 9-4 High pressure nozzle guide vane construction and cooling.

Accessory cooling and to prevent ingress of the mainstream gas into the

10. A considerable amount of heat is produced by turbine disc cavities.

some of the engine accessories, of which the

electrical generator is an example, and these may 13. Various sealing methods are used on gas

often require their own cooling circuit. When air is turbine engines. The choice of which method is

dependent upon the surrounding temperature and

used for cooling, the source may be the compressor pressure, wearability, heat generation, weight, space

or atmospheric air ducted from intake louvres in the available, ease of manufacture and ease of installa-

engine cowlings.

tion and removal. Some of the sealing methods are

11. When an accessory unit is cooled during flight described in the following paragraphs. A hypothetical

by atmospheric air it is usually necessary to provide turbine showing the usage of these seals is shown in

an induced circuit for use during static ground fig. 9-5.

running when there would be no external airflow. This Labyrinth seals

is achieved by allowing compressor delivery air to 14. This type of seal is widely used to retain oil in

pass through nozzles situated in the cooling air outlet bearing chambers and as a metering device to

duct of the accessory. The air velocity through the control internal airflows. Several variations of

nozzles create a low pressure area which forms an labyrinth seal design are shown in fig. 9-7.

ejector, so inducing a flow of atmospheric air through

the intake louvres. To ensure that the ejector system 15. A labyrinth seal comprises a finned rotating

only operates during ground running, the flow of air member with a static bore which is lined with a soft

from the compressor is controlled by a valve. A abradable material, or a high temperature

generator cooling system with an ejector is shown in honeycomb structure. On initial running of the engine

fig. 9-6. the fins lightly rub against the lining, cutting into it to

give a minimum clearance. The clearance varies

SEALING throughout the flight cycle, dependent upon the

thermal growth of the parts and the natural flexing of

12. Seals are used to prevent oil leakage from the the rotating members. Across each seal fin there is a

engine bearing chambers, to control cooling airflows pressure drop which results in a restricted flow of

89