Page 148 -

P. 148

Special Applications

and heat-treated high chrome iron. Natural rubber and other

elastomers are also frequently used as a liner for abrasive services as long

as they are chemically compatible with the slurry.

It is worth noting that hard metal and rubber impellers cannot be

machined to the necessary diameter in order to meet the required

operating conditions. Consequently, they have traditionally been belt-

driven and a change in operation is achieved by a change in sheave ratio

to give the rotational speed required.

8.1.4 Recessed impeller vortex pumps

In most slurry, the water tends to be used simply as a mode of transport

for the solid particles which usually impart the damage to the pump.

This is when the special materials are required for the casing and

impeller to resist such attack as discussed above.

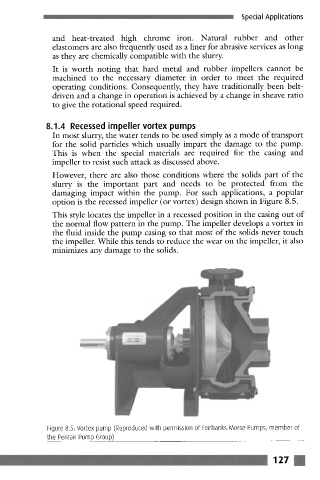

However, there are also those conditions where the solids part of the

slurry is the important part and needs to be protected from the

damaging impact within the pump. For such applications, a popular

option is the recessed impeller (or vortex) design shown in Figure 8.5.

This style locates the impeller in a recessed position in the casing out of

the normal flow pattern in the pump. The impeller develops a vortex in

the fluid inside the pump casing so that most of the solids never touch

the impeller. While this tends to reduce the wear on the impeller, it also

minimizes any damage to the solids.

Figure 8.5: Vortex pump (Reproduced with permission of Fairbanks Morse Pumps, member of

the Pentair Pump Group)

127 !