Page 143 -

P. 143

The Practical Pumping Handbook ~ ~:=-_ .............. ::::::::::::::::::::::::::::: :::::::::iiiiiiii ............

have little or no lubricant in the immediate area of the lip seals, thus

contributing to their early failure. In addition, the lip seal is a contact

seal that will inevitably groove the shaft.

7.9.3 lhe magnetic seals

This is a mature design whose use in centrifugal pumps has been

recently reintroduced as an option to the lip seal. A current double seal

design brings the rotating faces into full contact with the stationary

magnet to completely seal off the housing.

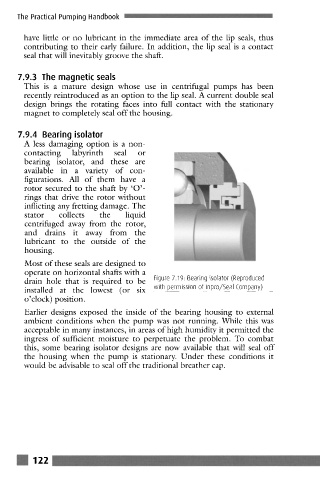

7.9.4 Bearing isolator

A less damaging option is a non-

contacting labyrinth seal or

bearing isolator, and these are

available in a variety of con-

figurations. All of them have a

rotor secured to the shaft by 'O'-

rings that drive the rotor without

inflicting any fretting damage. The

stator collects the liquid

centrifuged away from the rotor,

and drains it away from the

lubricant to the outside of the

housing.

Most of these seals are designed to

operate on horizontal shafts with a

drain hole that is required to be Figure 7.19: Bearing isolator (Reproduced

installed at the lowest (or six with permission of Inpro/Seal Company)

o'clock) position.

Earlier designs exposed the inside of the bearing housing to external

ambient conditions when the pump was not running. While this was

acceptable in many instances, in areas of high humidity it permitted the

ingress of sufficient moisture to perpetuate the problem. To combat

this, some bearing isolator designs are now available that will seal off

the housing when the pump is stationary. Under these conditions it

would be advisable to seal off the traditional breather cap.

122 . . . . . .