Page 85 -

P. 85

The Practical Pumping Handbook . . . . . . . . . . . . . . .

This condition can often be a result of pumping fermenting liquids or

foaming agents found in a wide variety of industries. It can also be a

result of pumping a liquid, such as condensate, that is close to its

boiling point.

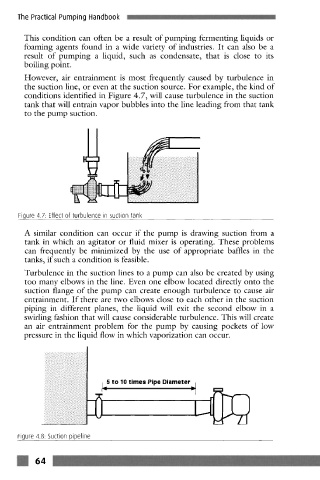

However, air entrainment is most frequently caused by turbulence in

the suction line, or even at the suction source. For example, the kind of

conditions identified in Figure 4.7, will cause turbulence in the suction

tank that will entrain vapor bubbles into the line leading from that tank

to the pump suction.

!iiii/ iili/iiiiiiiiiil

Figure 4.7: Effect of turbulence in suction tank

A similar condition can occur if the pump is drawing suction from a

tank in which an agitator or fluid mixer is operating. These problems

can frequently be minimized by the use of appropriate baffles in the

tanks, if such a condition is feasible.

Turbulence in the suction lines to a pump can also be created by using

too many elbows in the line. Even one elbow located directly onto the

suction flange of the pump can create enough turbulence to cause air

entrainment. If there are two elbows close to each other in the suction

piping in different planes, the liquid will exit the second elbow in a

swirling fashion that will cause considerable turbulence. This will create

an air entrainment problem for the pump by causing pockets of low

pressure in the liquid flow in which vaporization can occur.

i q5 to 10 times Pipe Diameter i

-[

Figure 4.8: Suction pipeline