Page 86 -

P. 86

Suction Conditions

The ideal situation is to provide the suction side with a straight run of

pipe, in a length equivalent to 5 to 10 times the diameter of that pipe,

between the suction reducer and the first obstruction in the line. This

will ensure the delivery of a uniform flow of liquid to the eye of the

impcllcr and avoid any turbulence and air entrainment.

As air entrainment causes the same pitting damage to the impeller in

precisely the same location as cavitation, it can be a little confusing,

particularly as both can occur simultaneously in the same service.

However, a quick comparison of the NPSHA and NPSHR, combined

with a visual review of the piping characteristics will usually help

identify the root cause of the so-called 'cavitation' and solve the air

entrainment problem.

4.7 Similarities and differences

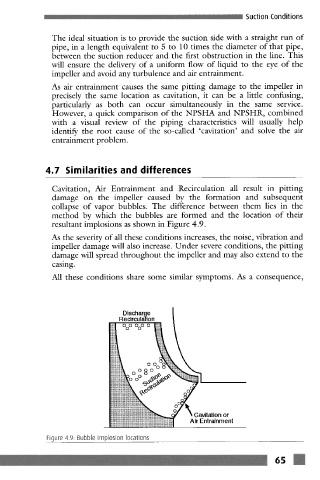

Cavitation, Air Entrainment and Recirculation all result in pitting

damage on the impeller caused by the formation and subsequent

collapse of vapor bubbles. The difference between them lies in the

method by which the bubbles are formed and the location of their

resultant implosions as shown in Figure 4.9.

As the severity of all these conditions increases, the noise, vibration and

impeller damage will also increase. Under severe conditions, the pitting

damage will spread throughout the impeller and may also extend to the

casing.

All these conditions share some similar symptoms. As a consequence,

Discharge

"i!i!

Figure 4.9: Bubble implosion locations

6s m