Page 115 - The Toyota Way Fieldbook

P. 115

92 THE TOYOTA WAY FIELDBOOK

Case Study: The Danger of Single-Piece Flow for Short

Cycle-Time Jobs

The move to making material flow from traditional “batch and queue”

methods has become somewhat of a fad. As with most fads, they can be

taken to an extreme, and negative consequences ensue. The single-piece

flow “fad” has, in many cases created reduced performance results.

Single-piece flow may not be the most efficient method for short cycle-

time operations (30 seconds or less).

A kaizen workshop was held with the objective of establishing single-

piece flow capability in the assembly operation. The product was an

assembled fitting requiring 13 seconds to complete. The takt time was

determined to be 5 seconds, based on the customer demand. The

work was divided among three operators, and a work cell (another

fad) was created to facilitate the passing of product between operators,

which is necessary for flow.

Several months later this work area was struggling to meet the customer

demand, and operators had returned to batching product between

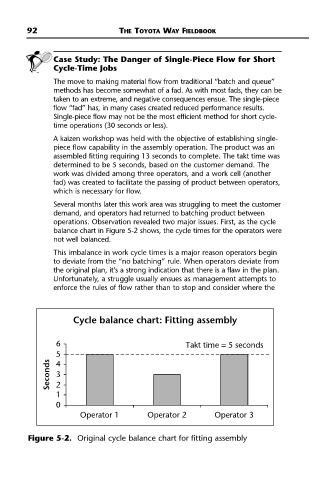

operations. Observation revealed two major issues. First, as the cycle

balance chart in Figure 5-2 shows, the cycle times for the operators were

not well balanced.

This imbalance in work cycle times is a major reason operators begin

to deviate from the “no batching” rule. When operators deviate from

the original plan, it’s a strong indication that there is a flaw in the plan.

Unfortunately, a struggle usually ensues as management attempts to

enforce the rules of flow rather than to stop and consider where the

Cycle balance chart: Fitting assembly

6 Takt time = 5 seconds

5

Seconds 3

4

2

1

0

Operator 1 Operator 2 Operator 3

Figure 5-2. Original cycle balance chart for fitting assembly