Page 111 - The Toyota Way Fieldbook

P. 111

88 THE TOYOTA WAY FIELDBOOK

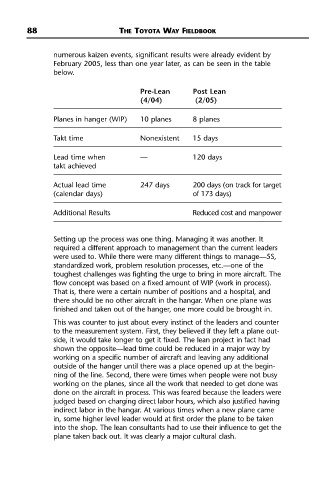

numerous kaizen events, significant results were already evident by

February 2005, less than one year later, as can be seen in the table

below.

Pre-Lean Post Lean

(4/04) (2/05)

Planes in hanger (WIP) 10 planes 8 planes

Takt time Nonexistent 15 days

Lead time when — 120 days

takt achieved

Actual lead time 247 days 200 days (on track for target

(calendar days) of 173 days)

Additional Results Reduced cost and manpower

Setting up the process was one thing. Managing it was another. It

required a different approach to management than the current leaders

were used to. While there were many different things to manage—5S,

standardized work, problem resolution processes, etc.—one of the

toughest challenges was fighting the urge to bring in more aircraft. The

flow concept was based on a fixed amount of WIP (work in process).

That is, there were a certain number of positions and a hospital, and

there should be no other aircraft in the hangar. When one plane was

finished and taken out of the hanger, one more could be brought in.

This was counter to just about every instinct of the leaders and counter

to the measurement system. First, they believed if they left a plane out-

side, it would take longer to get it fixed. The lean project in fact had

shown the opposite—lead time could be reduced in a major way by

working on a specific number of aircraft and leaving any additional

outside of the hanger until there was a place opened up at the begin-

ning of the line. Second, there were times when people were not busy

working on the planes, since all the work that needed to get done was

done on the aircraft in process. This was feared because the leaders were

judged based on charging direct labor hours, which also justified having

indirect labor in the hangar. At various times when a new plane came

in, some higher level leader would at first order the plane to be taken

into the shop. The lean consultants had to use their influence to get the

plane taken back out. It was clearly a major cultural clash.