Page 106 - The Toyota Way Fieldbook

P. 106

Chapter 5. Create Connected Process Flow 83

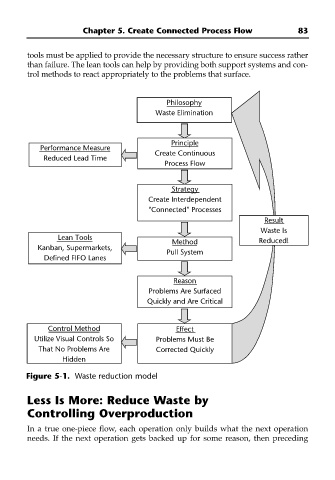

tools must be applied to provide the necessary structure to ensure success rather

than failure. The lean tools can help by providing both support systems and con-

trol methods to react appropriately to the problems that surface.

Philosophy

Waste Elimination

Principle

Performance Measure

Create Continuous

Reduced Lead Time

Process Flow

Strategy

Create Interdependent

"Connected" Processes

Result

Waste Is

Lean Tools

Method Reduced!

Kanban, Supermarkets,

Pull System

Defined FIFO Lanes

Reason

Problems Are Surfaced

Quickly and Are Critical

Control Method Effect

Utilize Visual Controls So Problems Must Be

That No Problems Are Corrected Quickly

Hidden

Figure 5-1. Waste reduction model

Less Is More: Reduce Waste by

Controlling Overproduction

In a true one-piece flow, each operation only builds what the next operation

needs. If the next operation gets backed up for some reason, then preceding