Page 207 - The Toyota Way Fieldbook

P. 207

Chapter 8. Build a Culture That Stops to Fix Problems 183

Operator Work Zone Operator Work Zone Operator Work Zone

Pull Cord

50% Response

Work Fixed time before

Position line stops

Visual

Stop

indicators of

work progress

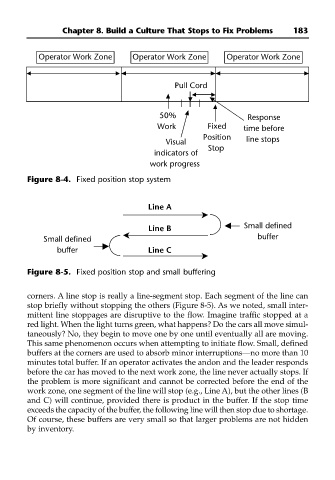

Figure 8-4. Fixed position stop system

Line A

Line B Small defined

Small defined buffer

buffer Line C

Figure 8-5. Fixed position stop and small buffering

corners. Aline stop is really a line-segment stop. Each segment of the line can

stop briefly without stopping the others (Figure 8-5). As we noted, small inter-

mittent line stoppages are disruptive to the flow. Imagine traffic stopped at a

red light. When the light turns green, what happens? Do the cars all move simul-

taneously? No, they begin to move one by one until eventually all are moving.

This same phenomenon occurs when attempting to initiate flow. Small, defined

buffers at the corners are used to absorb minor interruptions—no more than 10

minutes total buffer. If an operator activates the andon and the leader responds

before the car has moved to the next work zone, the line never actually stops. If

the problem is more significant and cannot be corrected before the end of the

work zone, one segment of the line will stop (e.g., Line A), but the other lines (B

and C) will continue, provided there is product in the buffer. If the stop time

exceeds the capacity of the buffer, the following line will then stop due to shortage.

Of course, these buffers are very small so that larger problems are not hidden

by inventory.