Page 203 - The Toyota Way Fieldbook

P. 203

Chapter 8. Build a Culture That Stops to Fix Problems 179

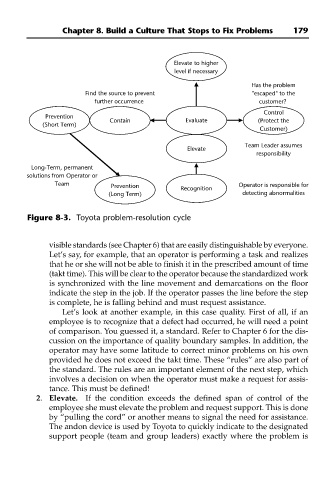

Elevate to higher

level if necessary

Has the problem

Find the source to prevent "escaped" to the

further occurrence customer?

Control

Prevention

Contain Evaluate (Protect the

(Short Term)

Customer)

Team Leader assumes

Elevate

responsibility

Long-Term, permanent

solutions from Operator or

Team Prevention Operator is responsible for

Recognition

(Long Term) detecting abnormalities

Figure 8-3. Toyota problem-resolution cycle

visible standards (see Chapter 6) that are easily distinguishable by everyone.

Let’s say, for example, that an operator is performing a task and realizes

that he or she will not be able to finish it in the prescribed amount of time

(takt time). This will be clear to the operator because the standardized work

is synchronized with the line movement and demarcations on the floor

indicate the step in the job. If the operator passes the line before the step

is complete, he is falling behind and must request assistance.

Let’s look at another example, in this case quality. First of all, if an

employee is to recognize that a defect had occurred, he will need a point

of comparison. You guessed it, a standard. Refer to Chapter 6 for the dis-

cussion on the importance of quality boundary samples. In addition, the

operator may have some latitude to correct minor problems on his own

provided he does not exceed the takt time. These “rules” are also part of

the standard. The rules are an important element of the next step, which

involves a decision on when the operator must make a request for assis-

tance. This must be defined!

2. Elevate. If the condition exceeds the defined span of control of the

employee she must elevate the problem and request support. This is done

by “pulling the cord” or another means to signal the need for assistance.

The andon device is used by Toyota to quickly indicate to the designated

support people (team and group leaders) exactly where the problem is