Page 198 - The Toyota Way Fieldbook

P. 198

174 THE TOYOTA WAY FIELDBOOK

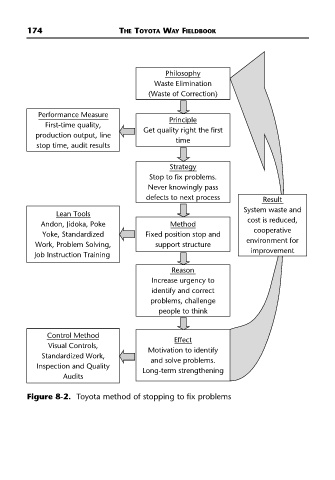

Philosophy

Waste Elimination

(Waste of Correction)

Performance Measure

Principle

First-time quality,

Get quality right the first

production output, line

time

stop time, audit results

Strategy

Stop to fix problems.

Never knowingly pass

defects to next process Result

System waste and

Lean Tools

cost is reduced,

Andon, Jidoka, Poke Method

cooperative

Yoke, Standardized Fixed position stop and

environment for

Work, Problem Solving, support structure

improvement

Job Instruction Training

Reason

Increase urgency to

identify and correct

problems, challenge

people to think

Control Method

Effect

Visual Controls,

Motivation to identify

Standardized Work,

and solve problems.

Inspection and Quality

Long-term strengthening

Audits

Figure 8-2. Toyota method of stopping to fix problems