Page 197 - The Toyota Way Fieldbook

P. 197

Chapter 8. Build a Culture That Stops to Fix Problems 173

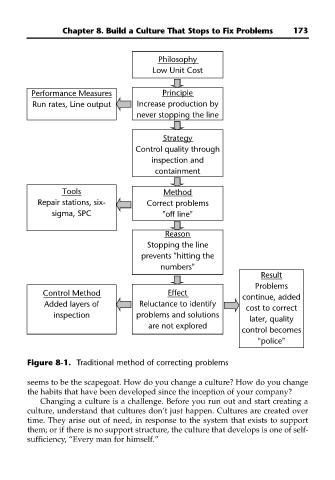

Philosophy

Low Unit Cost

Performance Measures Principle

Run rates, Line output Increase production by

never stopping the line

Strategy

Control quality through

inspection and

containment

Tools Method

Repair stations, six- Correct problems

sigma, SPC "off line"

Reason

Stopping the line

prevents "hitting the

numbers"

Result

Problems

Control Method Effect

continue, added

Added layers of Reluctance to identify

cost to correct

inspection problems and solutions

later, quality

are not explored

control becomes

"police"

Figure 8-1. Traditional method of correcting problems

seems to be the scapegoat. How do you change a culture? How do you change

the habits that have been developed since the inception of your company?

Changing a culture is a challenge. Before you run out and start creating a

culture, understand that cultures don’t just happen. Cultures are created over

time. They arise out of need, in response to the system that exists to support

them; or if there is no support structure, the culture that develops is one of self-

sufficiency, “Every man for himself.”