Page 320 - The Toyota Way Fieldbook

P. 320

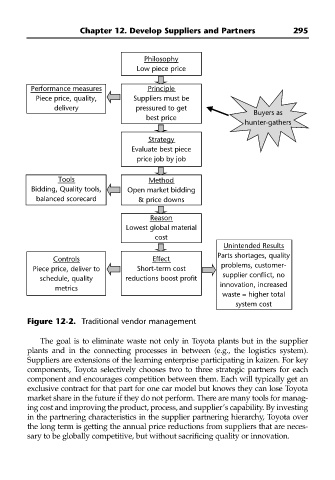

Chapter 12. Develop Suppliers and Partners 295

Philosophy

Low piece price

Performance measures Principle

Piece price, quality, Suppliers must be

delivery pressured to get

Buyers as

best price

hunter-gathers

Strategy

Evaluate best piece

price job by job

Tools Method

Bidding, Quality tools, Open market bidding

balanced scorecard & price downs

Reason

Lowest global material

cost

Unintended Results

Parts shortages, quality

Controls Effect

problems, customer-

Piece price, deliver to Short-term cost

supplier conflict, no

schedule, quality reductions boost profit

innovation, increased

metrics

waste = higher total

system cost

Figure 12-2. Traditional vendor management

The goal is to eliminate waste not only in Toyota plants but in the supplier

plants and in the connecting processes in between (e.g., the logistics system).

Suppliers are extensions of the learning enterprise participating in kaizen. For key

components, Toyota selectively chooses two to three strategic partners for each

component and encourages competition between them. Each will typically get an

exclusive contract for that part for one car model but knows they can lose Toyota

market share in the future if they do not perform. There are many tools for manag-

ing cost and improving the product, process, and supplier’s capability. By investing

in the partnering characteristics in the supplier partnering hierarchy, Toyota over

the long term is getting the annual price reductions from suppliers that are neces-

sary to be globally competitive, but without sacrificing quality or innovation.