Page 321 - The Toyota Way Fieldbook

P. 321

296 THE TOYOTA WAY FIELDBOOK

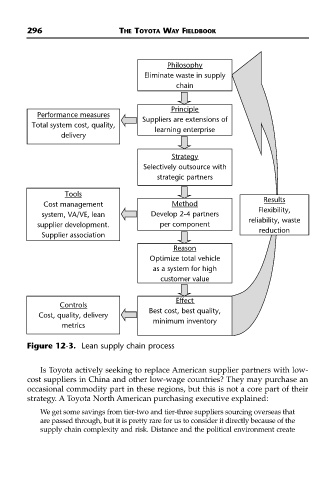

Philosophy

Eliminate waste in supply

chain

Principle

Performance measures

Suppliers are extensions of

Total system cost, quality,

learning enterprise

delivery

Strategy

Selectively outsource with

strategic partners

Tools

Results

Cost management Method

Flexibility,

system, VA/VE, lean Develop 2-4 partners

reliability, waste

supplier development. per component

reduction

Supplier association

Reason

Optimize total vehicle

as a system for high

customer value

Effect

Controls

Best cost, best quality,

Cost, quality, delivery

minimum inventory

metrics

Figure 12-3. Lean supply chain process

Is Toyota actively seeking to replace American supplier partners with low-

cost suppliers in China and other low-wage countries? They may purchase an

occasional commodity part in these regions, but this is not a core part of their

strategy. A Toyota North American purchasing executive explained:

We get some savings from tier-two and tier-three suppliers sourcing overseas that

are passed through, but it is pretty rare for us to consider it directly because of the

supply chain complexity and risk. Distance and the political environment create