Page 353 - The Toyota Way Fieldbook

P. 353

328 THE TOYOTA WAY FIELDBOOK

COST

CUSTOMER

SERVICE

PRODUCTIVITY QUALITY

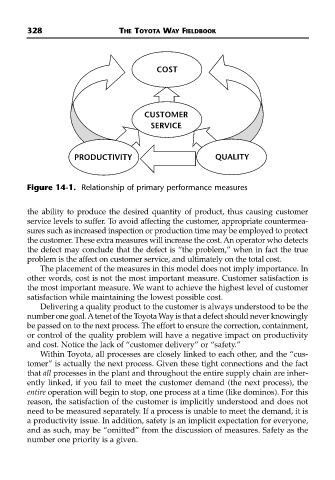

Figure 14-1. Relationship of primary performance measures

the ability to produce the desired quantity of product, thus causing customer

service levels to suffer. To avoid affecting the customer, appropriate countermea-

sures such as increased inspection or production time may be employed to protect

the customer. These extra measures will increase the cost. An operator who detects

the defect may conclude that the defect is “the problem,” when in fact the true

problem is the affect on customer service, and ultimately on the total cost.

The placement of the measures in this model does not imply importance. In

other words, cost is not the most important measure. Customer satisfaction is

the most important measure. We want to achieve the highest level of customer

satisfaction while maintaining the lowest possible cost.

Delivering a quality product to the customer is always understood to be the

number one goal. Atenet of the Toyota Way is that a defect should never knowingly

be passed on to the next process. The effort to ensure the correction, containment,

or control of the quality problem will have a negative impact on productivity

and cost. Notice the lack of “customer delivery” or “safety.”

Within Toyota, all processes are closely linked to each other, and the “cus-

tomer” is actually the next process. Given these tight connections and the fact

that all processes in the plant and throughout the entire supply chain are inher-

ently linked, if you fail to meet the customer demand (the next process), the

entire operation will begin to stop, one process at a time (like dominos). For this

reason, the satisfaction of the customer is implicitly understood and does not

need to be measured separately. If a process is unable to meet the demand, it is

a productivity issue. In addition, safety is an implicit expectation for everyone,

and as such, may be “omitted” from the discussion of measures. Safety as the

number one priority is a given.