Page 477 - The Toyota Way Fieldbook

P. 477

446 THE TOYOTA WAY FIELDBOOK

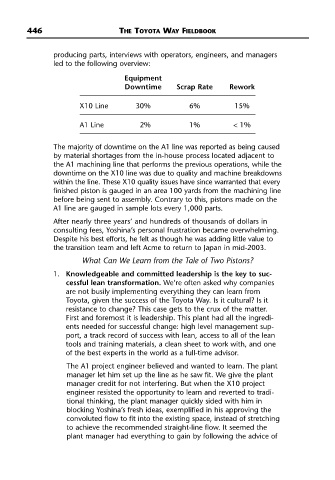

producing parts, interviews with operators, engineers, and managers

led to the following overview:

Equipment

Downtime Scrap Rate Rework

X10 Line 30% 6% 15%

A1 Line 2% 1% < 1%

The majority of downtime on the A1 line was reported as being caused

by material shortages from the in-house process located adjacent to

the A1 machining line that performs the previous operations, while the

downtime on the X10 line was due to quality and machine breakdowns

within the line. These X10 quality issues have since warranted that every

finished piston is gauged in an area 100 yards from the machining line

before being sent to assembly. Contrary to this, pistons made on the

A1 line are gauged in sample lots every 1,000 parts.

After nearly three years’ and hundreds of thousands of dollars in

consulting fees, Yoshina’s personal frustration became overwhelming.

Despite his best efforts, he felt as though he was adding little value to

the transition team and left Acme to return to Japan in mid-2003.

What Can We Learn from the Tale of Two Pistons?

1. Knowledgeable and committed leadership is the key to suc-

cessful lean transformation. We’re often asked why companies

are not busily implementing everything they can learn from

Toyota, given the success of the Toyota Way. Is it cultural? Is it

resistance to change? This case gets to the crux of the matter.

First and foremost it is leadership. This plant had all the ingredi-

ents needed for successful change: high level management sup-

port, a track record of success with lean, access to all of the lean

tools and training materials, a clean sheet to work with, and one

of the best experts in the world as a full-time advisor.

The A1 project engineer believed and wanted to learn. The plant

manager let him set up the line as he saw fit. We give the plant

manager credit for not interfering. But when the X10 project

engineer resisted the opportunity to learn and reverted to tradi-

tional thinking, the plant manager quickly sided with him in

blocking Yoshina’s fresh ideas, exemplified in his approving the

convoluted flow to fit into the existing space, instead of stretching

to achieve the recommended straight-line flow. It seemed the

plant manager had everything to gain by following the advice of