Page 74 - The Toyota Way Fieldbook

P. 74

Chapter 3. Starting the Journey of Waste Reduction 51

Stabilize

Create

Flow

Level

Standardize Standardize

Incrementally

Create

Standardize Stabilize

Flow

Level

Create Incrementally

Stabilize Flow Create

Flow

Stabilize

Level

Level Standardize

Incrementally Incrementally Stabilize

Create

Standardize Flow

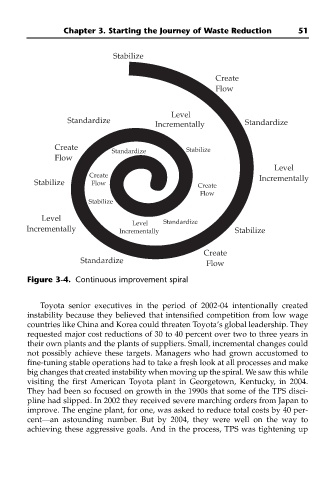

Figure 3-4. Continuous improvement spiral

Toyota senior executives in the period of 2002-04 intentionally created

instability because they believed that intensified competition from low wage

countries like China and Korea could threaten Toyota’s global leadership. They

requested major cost reductions of 30 to 40 percent over two to three years in

their own plants and the plants of suppliers. Small, incremental changes could

not possibly achieve these targets. Managers who had grown accustomed to

fine-tuning stable operations had to take a fresh look at all processes and make

big changes that created instability when moving up the spiral. We saw this while

visiting the first American Toyota plant in Georgetown, Kentucky, in 2004.

They had been so focused on growth in the 1990s that some of the TPS disci-

pline had slipped. In 2002 they received severe marching orders from Japan to

improve. The engine plant, for one, was asked to reduce total costs by 40 per-

cent—an astounding number. But by 2004, they were well on the way to

achieving these aggressive goals. And in the process, TPS was tightening up