Page 208 - The Tribology Handbook

P. 208

B9 Screws

Screws are used as linear actuators or jacks and can generate substantial axial forces. They can operate with an external

drive to either the screw or the nut, and the driving system often incorporates a worm gear in order to obtain a high

reduction ratio.

TYPES OF SCREW

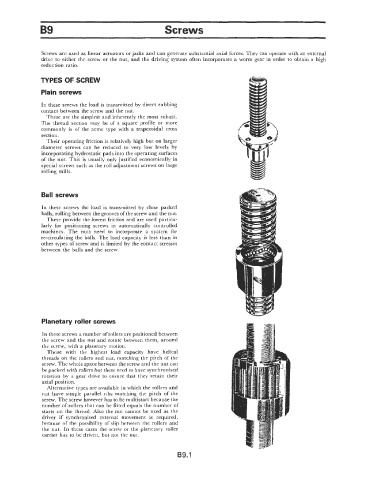

Plain screws

In these screws the load is transmitted by direct rubbing

contact between the screw and the nut.

These are the simplest and inherently the most robust.

The thread section may be of a square profile or more

commonly is of the acme type with a trapezoidal cross

section.

Their operating friction is relatively high but on larger

diameter screws can be reduced to very low levels by

incorporating hydrostatic pads into the operating surfaces

of the nut. This is usually only justified economically in

special screws such as the roll adjustment screws on large

rolling mills.

Ball screws

In these screws the load is transmitted by close packed

balls, rolling between the grooves of the screw and the nut.

These provide the lowest friction and are used particu-

larly for positioning screws in automatically controlled

machines. The nuts need to incorporate a system for

re-circulating the balls. The load capacity is less than in

other types of screw and is limited by the contact stresses

between the balls and the screw.

Planetary roller screws

In these screws a number of rollers are positioned between

the screw and the nut and rotate between them, around

the screw, with a planetary motion.

Those with the highest load capacity have helical

threads on the rollers and nut, matching the pitch of the

screw. The whole space between the screw and the nut can

be packed with rollers but these need to have synchronised

rotation by a gear drive to ensure that they retain their

axial position.

Alternative types are available in which the rollers and

nut have simple parallel ribs matching the pitch of the

screw. The screw however has to be multistart because the

number of rollers that can be fitted equals the number of

starts on the thread. Also the nut cannot be used as the

driver if synchronised external movement is required,

because of the possibility of slip between the rollers and

the nut. In these cases the screw or the planetary roller

carrier has to be driven. but not the nut.

B9.1