Page 22 - The Tribology Handbook

P. 22

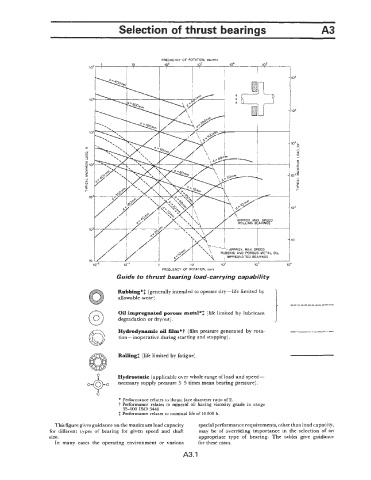

Selection of thrust bearings A3

FREQUENCY OF ROTATION, revlmin

I 10 lo2 10’

FREQUENCY OF ROTATION, reds

Guide to thrust Bearing load-carrying capability

Rubbing*$ (generally intended to operate dry-life limited by

allowable wear).

-------------

Oil impregnated porous metal*$ (life limited by lubricant

degradation or dryout).

Hydrodynamic oil film*? (film pressure generated by rota- ---.---

tion-inoperative during starting and stopping).

Rolling$ (life limited by fatigue)

Hydrostatic (applicable over whole range of load and speed-

necessary supply pressure 3-5 times mean bearing pressure).

* Performance relates to thrust face diameter ratio of 2.

t Performance relates to mineral oil having viscosity grade in range

32-100 IS0 3448

$ Performance relates to nominal life of 10 000 h.

This figure gives guidance on the maximum load capacity special performance requirements, other than load capacity,

for different types of bearing for given speed and shaft may be of overriding importance in the selection of an

size. appropriate type of bearing. The tables give guidance

In many cases the operating environment or various for these cases.

A3.1