Page 341 - The Tribology Handbook

P. 341

Lubrication of flexible couplings c11

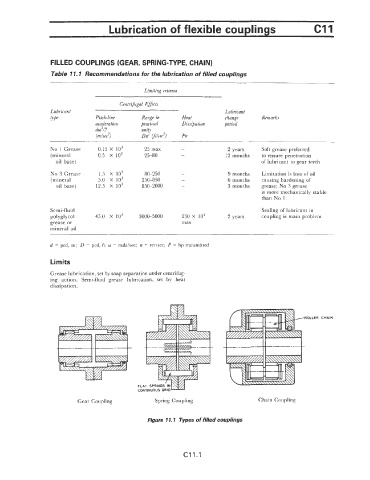

FILLED COUPLINGS (GEAR, SPRING-TYPE, CHAIN)

ble f 1. 1 Recommendations for the lubrication of filled couplings

Limiting criteria

Centn fuga1 Effects

Lubricant Lubricant

OPe Pitch-line Range in Heat change Remark3

acceleration practical Dissipation period

dm2/2 units

(I?l/SK?) Dn2 @/sec2) Pn

No 1 Grease 0.15 x 1oI3 25 max - 2 years Soft grease preferred

(mineral 0.5 x io3 25-80 - 12 months to ensure penetration

oil base) of lubricant to gear teeth

No 3 Grease 1.5 x io3 80-250 - 9 months Limitation is loss of oil

(mineral 5.0 x io3 250-850 - 6 months causing hardening of

oil base) 12.5 x io3 85CL2000 - 3 months grease; No 3 grease

is more mechanically stable

than No 1.

Semi- fluid Sealing of lubricant in

polygly col 45.0 x io3 300&5000 230 x io3 2 years coupling is main problem

grease or max

mineral oil

d = pcd, m; D = pcd, ft; w = rads/sec; n = revisec; P = hp transmitted

Limits

Grease lubrication, set by soap separation under centrifug-

ing action. Semi-fluid grease lubrication, set by heat

dissipation.

'ROLLER CHAIN

Y---tt----t

Gear Coupling Spring Coupling Chain Coupling

Figure 11. I Types of filled couplings

c11.1