Page 344 - The Tribology Handbook

P. 344

c12 Wire rope lubrication

LUBRICATION OF WIRE ROPES IN SERVICE

(1) (2) (3) (4) (5)

Operating Ropes working in Ropes subject to Ropes working As (3) but for Standing ropes

conditions industrial or heavy wear over sheaves friction drive not subject to

marine where (1) and applications bending

environments (2) are not

critical

Predominant Corrosion Abrasion Fatigue Fatigue-corrosion Corrosion

Cause of

rope

deterioration

Typical Cranes and derricks Mine haulage, Cranes and grabs, Lift suspension, Pendant ropes for

applications working on excavator jib suspension corn pema ting cranes and

ships, on draglines, ropes, piling, and governor excavators. Guys

docksides, or in scrapers and percussion and ropes, mine for masts and

polluted slushers drilling hoist ropes on chimneys

atmospheres friction winders

Dressing Good penetration Good antiwear Good penetration Non slip property. Good corrosion

requirements to rope interior. properties. Good to rope interior. Good penetration protection.

Ability to displace adhesion to rope. Good lubrication to rope interior. Resistance to

moisture. Resistance to properties. Ability to ‘wash off ’.

Internal and removal by Resistance to displace Resistance to

external mechanical ‘fling off’ moisture. surface cracking

corrosion forces Internal and

protection. external

Resistance to corrosion

‘wash off ’. protection

Resistance eo

emulsification

=YPf !f Usually a Usually a very Usually a good Usually a solvent- Usually a

lubricant formulation viscous oil or general purpose dispersed relatively thick,

containing soft grease lubricating oil temporary bituminous

solvent leaving containing of about SAE corrosion compound with

a thick MoS, or 30 viscosity preventative solvent added

(0.1 mm) soft graphite. leaving a thin, to assist

grease film Tackiness semi-hard film application

additives can

be of advantage

Application Manual or Manual or Mechanical Normally by hand Normally by hand

technique mechanical mechanical

Frequency of Monthly Weekly 10/20 cycles per Monthly Six monthly/

applications* day 2 years

* The periods indicated are for the general case. The frequency of operation, the environmental conditions and the economics of service

dressing will more correctly dictate the period required.

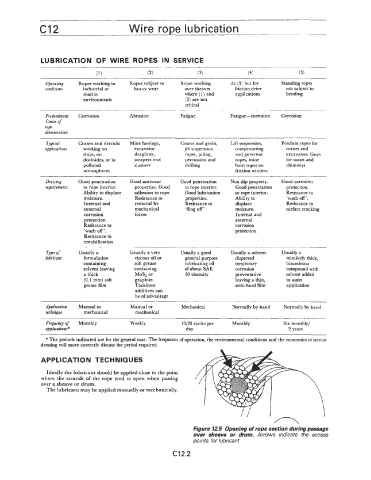

APPLICATION TECHNIQUES

/

Ideally the lubricant should be applied close to the point // ,/

/’

where the strands of the rope tend to open when passing

over a sheave or drum. /

The lubricant may be applied manually or mechanically.

7 I

I

J

n

t

I

Figure 12.5 Opening of rope section during passage

over sheave or drum. Arrows indicate the access

points for lubricant

c12.2