Page 200 - Welding of Aluminium and its Alloys

P. 200

Welding procedure and welder approval 183

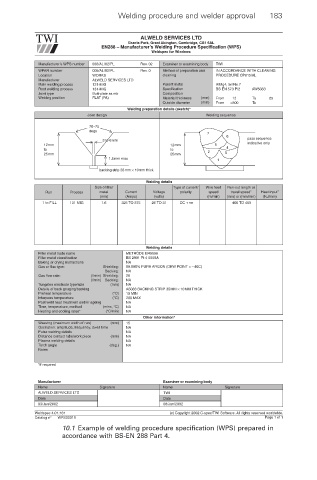

TWI ALWELD SERVICES LTD

Granta Park, Great Abington, Cambridge, CB1 6AL

EN288 – Manufacturer’s Welding Procedure Specification (WPS)

Weldspec for Windows

Manufacturer’s WPS number 036/AL /82/PL Rev. 02 Examiner or examining body TWI

WPAR number 005/AL /82/PL Rev. 0 Method of preparation and IN ACCORDANCE WITH CLEANING

Location WORKS cleaning PROCEDURE CP015/AL

Manufacturer ALWELD SERVICES LTD

Main welding process 131-MIG Parent metal AIMg4, 5mNo.7

Root welding process 131-MIG Specification BS EN 573 PI2 AW5083

Joint type Butt-plate ss mb Composition

Welding position FLAT (PA) Material thickness (mm) From 12 To 25

Outside diameter (mm) From >500 To

Welding preparation details (sketch)*

Joint design Welding sequence

70–75

degs

7

6

3 to 6 mm pass sequence

12 mm 12 mm 5 indicative only

to to 2 4

25 mm 25 mm 3

1.5 mm max 1

backing strip 35 mm ¥ 10 mm thick

Welding details

Size of filler Type of current/ Wire feed Run-out length or

Run Process metal Current Voltage polarity speed travel speed* Heat input*

(mm) (Amps) (volts) (m/min) (mm) or (mm/min) (KJ/mm)

1 to FILL 131 MIG 1.6 325 TO 375 26 TO 31 DC + ve 400 TO 450

Welding details

Filler metal trade name METRODE ER5556

Filler metal classification BS 2901 Pt 4 5556A

Baking or drying instructions NA

Gas or flux type: Shielding: 99.995% PURE ARGON (DEW POINT < – 40C)

Backing: NA

Gas flow rate: (l/min) Shielding: 26

(l/min) Backing: NA

Tungsten electrode type/size (mm) NA

Details of back gouging/backing A5083 BACKING STRIP 35 MM ¥ 10 MM THICK

Preheat temperature (°C) 10 MIN

Interpass temperature (°C) 200 MAX

Post weld heat treatment and/or ageing NA

Time, temperature, method (mins, °C) NA

Heating and cooling rates* (°C/min) NA

Other information*

Weaving (maximum width of run) (mm) 15

Oscillation: amplitude, frequency, dwell time NA

Pulse welding details NA

Distance contact tube/work piece (mm) NA

Plasma welding details NA

Torch angle (deg.) NA

Notes

*If required

Manufacturer Examiner or examining body

Name Signature Name Signature

ALWELD SERVICES LTD TWI

Date Date

03/Jan/2002 08/Jan/2002

Weldspec 4.01.161 (c) Copyright 2002 C-spec/TWI Software. All rights reserved worldwide.

Catalog n° WPS00019 Page 1 of 1

10.1 Example of welding procedure specification (WPS) prepared in

accordance with BS-EN 288 Part 4.