Page 195 - Welding of Aluminium and its Alloys

P. 195

178 The welding of aluminium and its alloys

Flashing Upset

Upset length

Flashing length

Movement

Force Upset force

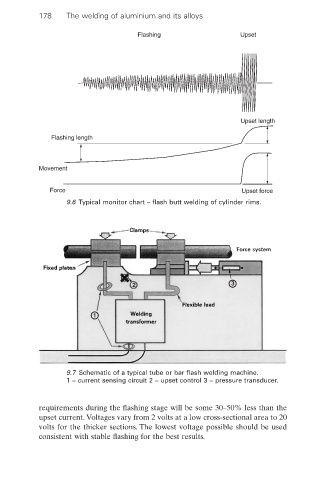

9.6 Typical monitor chart – flash butt welding of cylinder rims.

2 3

1

9.7 Schematic of a typical tube or bar flash welding machine.

1 = current sensing circuit 2 = upset control 3 = pressure transducer.

requirements during the flashing stage will be some 30–50% less than the

upset current. Voltages vary from 2 volts at a low cross-sectional area to 20

volts for the thicker sections. The lowest voltage possible should be used

consistent with stable flashing for the best results.