Page 194 - Welding of Aluminium and its Alloys

P. 194

Resistance welding processes 177

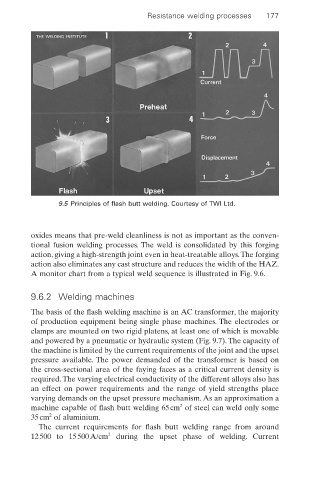

9.5 Principles of flash butt welding. Courtesy of TWI Ltd.

oxides means that pre-weld cleanliness is not as important as the conven-

tional fusion welding processes. The weld is consolidated by this forging

action, giving a high-strength joint even in heat-treatable alloys.The forging

action also eliminates any cast structure and reduces the width of the HAZ.

A monitor chart from a typical weld sequence is illustrated in Fig. 9.6.

9.6.2 Welding machines

The basis of the flash welding machine is an AC transformer, the majority

of production equipment being single phase machines. The electrodes or

clamps are mounted on two rigid platens, at least one of which is movable

and powered by a pneumatic or hydraulic system (Fig. 9.7). The capacity of

the machine is limited by the current requirements of the joint and the upset

pressure available. The power demanded of the transformer is based on

the cross-sectional area of the faying faces as a critical current density is

required. The varying electrical conductivity of the different alloys also has

an effect on power requirements and the range of yield strengths place

varying demands on the upset pressure mechanism.As an approximation a

2

machine capable of flash butt welding 65cm of steel can weld only some

2

35cm of aluminium.

The current requirements for flash butt welding range from around

12500 to 15500A/cm 2 during the upset phase of welding. Current