Page 213 - Welding of Aluminium and its Alloys

P. 213

196 The welding of aluminium and its alloys

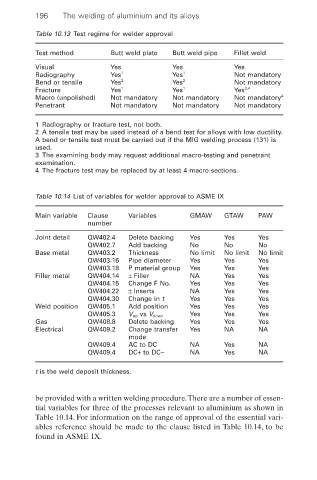

Table 10.13 Test regime for welder approval

Test method Butt weld plate Butt weld pipe Fillet weld

Visual Yes Yes Yes

Radiography Yes 1 Yes 1 Not mandatory

Bend or tensile Yes 2 Yes 2 Not mandatory

Fracture Yes 1 Yes 1 Yes 3,4

Macro (unpolished) Not mandatory Not mandatory Not mandatory 4

Penetrant Not mandatory Not mandatory Not mandatory

1 Radiography or fracture test, not both.

2 A tensile test may be used instead of a bend test for alloys with low ductility.

A bend or tensile test must be carried out if the MIG welding process (131) is

used.

3 The examining body may request additional macro-testing and penetrant

examination.

4 The fracture test may be replaced by at least 4 macro-sections.

Table 10.14 List of variables for welder approval to ASME IX

Main variable Clause Variables GMAW GTAW PAW

number

Joint detail QW402.4 Delete backing Yes Yes Yes

QW402.7 Add backing No No No

Base metal QW403.2 Thickness No limit No limit No limit

QW403.16 Pipe diameter Yes Yes Yes

QW403.18 P material group Yes Yes Yes

Filler metal QW404.14 ± Filler NA Yes Yes

QW404.15 Change F No. Yes Yes Yes

QW404.22 ± Inserts NA Yes Yes

QW404.30 Change in t Yes Yes Yes

Weld position QW405.1 Add position Yes Yes Yes

QW405.3 V up vs V down Yes Yes Yes

Gas QW408.8 Delete backing Yes Yes Yes

Electrical QW409.2 Change transfer Yes NA NA

mode

QW409.4 AC to DC NA Yes NA

QW409.4 DC+ to DC- NA Yes NA

t is the weld deposit thickness.

be provided with a written welding procedure.There are a number of essen-

tial variables for three of the processes relevant to aluminium as shown in

Table 10.14. For information on the range of approval of the essential vari-

ables reference should be made to the clause listed in Table 10.14, to be

found in ASME IX.