Page 218 - Welding of Aluminium and its Alloys

P. 218

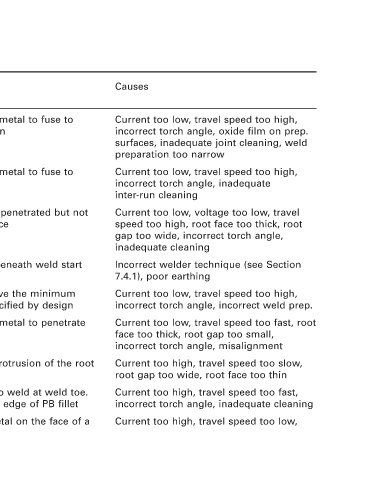

Current too low, travel speed too high, incorrect torch angle, oxide film on prep. surfaces, inadequate joint cleaning, weld Current too low, travel speed too high, incorrect torch angle, inadequate Current too low, voltage too low, travel speed too high, root face too thick, root gap too wide,

Causes preparation too narrow inter-run cleaning inadequate cleaning 7.4.1), poor earthing

Failure of weld metal to fuse to Failure of weld metal to fuse to Root bead fully penetrated but not Lack of fusion beneath weld start Failure to achieve the minimum penetration specified by design Failure of weld metal to penetrate Unacceptable protrusion of the root Notch parallel to wel

Description weld preparation preceding run fused to root face position fully root faces bead

Weld defects, description and causes Defect Name Lack of side wall fusion Lack of inter-run fusion Lack of root fusion Poor restart (cold start) Lack of penetration Insufficient (lack of) root penetration Excess penetration Root or face undercut Excess convexity

Table 11.1 ISO 6520 Defect no. 4011 (Fig. 11.1) 4012 (Fig. 11.1) 4013 (Fig. 11.1) 517 402 4021 (Fig. 11.2) 504 (Fig. 11.3) 501 (Fig. 11.4) 502 (butt)