Page 220 - Welding of Aluminium and its Alloys

P. 220

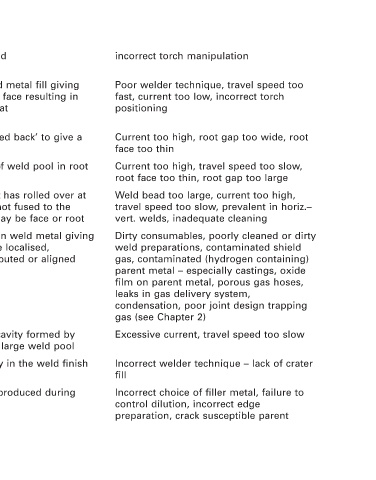

incorrect torch manipulation Poor welder technique, travel speed too fast, current too low, incorrect torch positioning Current too high, root gap too wide, root face too thin Current too high, travel speed too slow, root face too thin, root gap too large Weld bead too large, current too high, travel spee

butt or fillet weld Insufficient weld metal fill giving groove on weld face resulting in insufficient throat Root pass ‘sucked back’ to give a shallow groove Localised loss of weld pool in root Weld metal that has rolled over at the edges and not fused to the parent metal. May be face or root Gas entrapped

Excess weld metal (excess cap height) Incomplete fill (face concavity or missed edge). Insufficient throat in fillet welds Root concavity Burn-through Overlap (roll-over) Porosity Worm-hole (piping) Crater pipe Solidification cracking

503 (fillet) (Fig. 11.5) 511 (Fig. 11.6) 515 (Fig. 11.7) 510 506 (Fig. 11.8) 201 2016 2024 100