Page 225 - Welding of Aluminium and its Alloys

P. 225

Weld defects and quality control 205

static or dynamic loading, temperature and corrosive conditions and the

consequences of failure.

11.3 Non-destructive testing methods

NDE may be used to reveal defects that would be difficult or impossible to

detect by visual examination. The techniques are used during manufacture

as a quality control tool to determine the quality of the work. The extent

of NDE depends upon the application and the criticality of the joint and is

generally specified in the relevant application standards or contract speci-

fication. It is important for NDE to be included in the planning of the

fabrication process as it can require substantial time and resources. Full

account of this must be taken if disruption of production and delays to the

programme are to be avoided.

The requirement to perform NDE must also be taken into account during

the design phase. As with welding, access for NDE must be planned into

the component. The implication of this is that both welding engineers and

designers must be conversant with the techniques and their limitations if

the processes are to be used effectively.

11.3.1 Penetrant examination

This is a technique that is capable of detecting surface breaking defects only.

It relies upon a coloured or fluorescent dye, sprayed upon the surface,

penetrating these defects. After cleaning the excess from the surface, the

dye within the defect is drawn to the surface by spraying on a developer in

the case of the colour contrast dye or by exposing the surface to ultra-violet

light. The defect is revealed by the dye staining the developer or by

fluorescing (Fig. 11.9).

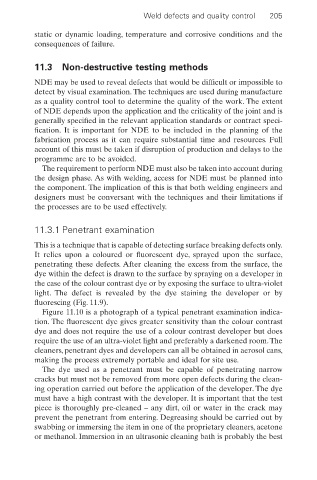

Figure 11.10 is a photograph of a typical penetrant examination indica-

tion. The fluorescent dye gives greater sensitivity than the colour contrast

dye and does not require the use of a colour contrast developer but does

require the use of an ultra-violet light and preferably a darkened room.The

cleaners, penetrant dyes and developers can all be obtained in aerosol cans,

making the process extremely portable and ideal for site use.

The dye used as a penetrant must be capable of penetrating narrow

cracks but must not be removed from more open defects during the clean-

ing operation carried out before the application of the developer. The dye

must have a high contrast with the developer. It is important that the test

piece is thoroughly pre-cleaned – any dirt, oil or water in the crack may

prevent the penetrant from entering. Degreasing should be carried out by

swabbing or immersing the item in one of the proprietary cleaners, acetone

or methanol. Immersion in an ultrasonic cleaning bath is probably the best