Page 229 - Welding of Aluminium and its Alloys

P. 229

Weld defects and quality control 209

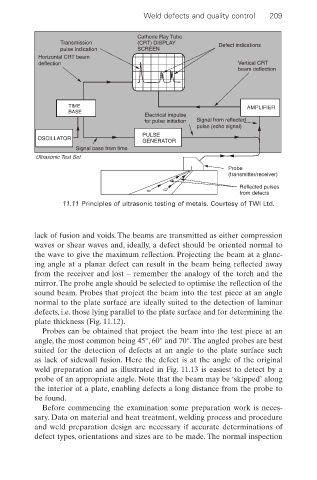

Cathode Ray Tube

Transmission (CRT) DISPLAY Defect indications

pulse indication SCREEN

Horizontal CRT beam

deflection Vertical CRT

beam deflection

TIME AMPLIFIER

BASE

Electrical impulse

for pulse initiation Signal from reflected

pulse (echo signal)

PULSE

OSCILLATOR

GENERATOR

Signal base from time

Ultrasonic Test Set

Probe

(transmitter/receiver)

Reflected pulses

from defects

11.11 Principles of ultrasonic testing of metals. Courtesy of TWI Ltd.

lack of fusion and voids. The beams are transmitted as either compression

waves or shear waves and, ideally, a defect should be oriented normal to

the wave to give the maximum reflection. Projecting the beam at a glanc-

ing angle at a planar defect can result in the beam being reflected away

from the receiver and lost – remember the analogy of the torch and the

mirror.The probe angle should be selected to optimise the reflection of the

sound beam. Probes that project the beam into the test piece at an angle

normal to the plate surface are ideally suited to the detection of laminar

defects, i.e. those lying parallel to the plate surface and for determining the

plate thickness (Fig. 11.12).

Probes can be obtained that project the beam into the test piece at an

angle, the most common being 45°, 60° and 70°. The angled probes are best

suited for the detection of defects at an angle to the plate surface such

as lack of sidewall fusion. Here the defect is at the angle of the original

weld preparation and as illustrated in Fig. 11.13 is easiest to detect by a

probe of an appropriate angle. Note that the beam may be ‘skipped’ along

the interior of a plate, enabling defects a long distance from the probe to

be found.

Before commencing the examination some preparation work is neces-

sary. Data on material and heat treatment, welding process and procedure

and weld preparation design are necessary if accurate determinations of

defect types, orientations and sizes are to be made. The normal inspection