Page 226 - Welding of Aluminium and its Alloys

P. 226

206 The welding of aluminium and its alloys

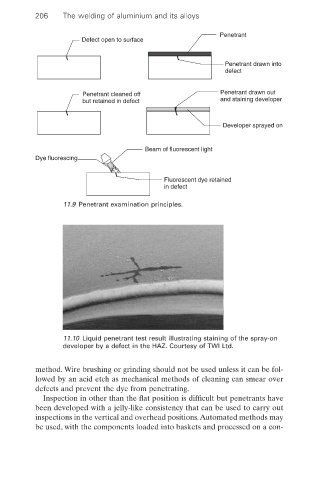

Penetrant

Defect open to surface

Penetrant drawn into

defect

Penetrant cleaned off Penetrant drawn out

but retained in defect and staining developer

Developer sprayed on

Beam of fluorescent light

Dye fluorescing

Fluorescent dye retained

in defect

11.9 Penetrant examination principles.

11.10 Liquid penetrant test result illustrating staining of the spray-on

developer by a defect in the HAZ. Courtesy of TWI Ltd.

method. Wire brushing or grinding should not be used unless it can be fol-

lowed by an acid etch as mechanical methods of cleaning can smear over

defects and prevent the dye from penetrating.

Inspection in other than the flat position is difficult but penetrants have

been developed with a jelly-like consistency that can be used to carry out

inspections in the vertical and overhead positions.Automated methods may

be used, with the components loaded into baskets and processed on a con-