Page 222 - Welding of Aluminium and its Alloys

P. 222

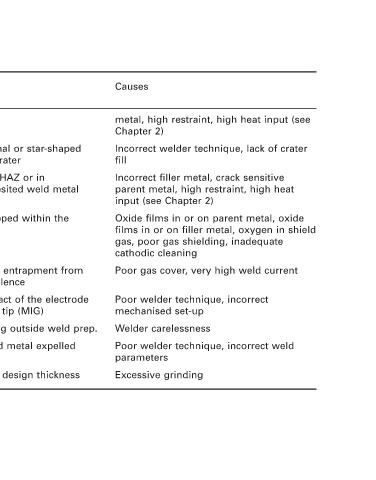

metal, high restraint, high heat input (see Incorrect welder technique, lack of crater Incorrect filler metal, crack sensitive parent metal, high restraint, high heat Oxide films in or on parent metal, oxide films in or on filler metal, oxygen in shield gas, poor gas shielding, inadequate Poor gas c

Causes Chapter 2) fill input (see Chapter 2) cathodic cleaning mechanised set-up Welder carelessness parameters Excessive grinding

Short longitudinal or star-shaped Cracking in the HAZ or in previously deposited weld metal Oxide films trapped within the Excessive oxide entrapment from Accidental contact of the electrode (TIG) or contact tip (MIG) Accidental arcing outside weld prep. Droplets of weld metal expelled

Description crack in finish crater weld metal weld pool turbulence from weld pool

Defect Name Crater cracking Liquation cracking Oxide entrapment Puckering Tungsten or copper inclusions Stray arc strike Spatter Underflushing

(cont.)

Table 11.1 ISO 6520 Defect no. 104 100 303 3034 3041 (tungsten) 3042 (copper) 602 602 606