Page 143 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 143

116 Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

3.3.2.3 Some examples at KIT: The THEADES (LBE)

and KASOLA (Na) loops

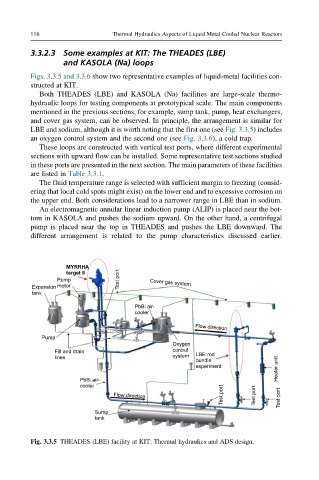

Figs. 3.3.5 and 3.3.6 show two representative examples of liquid-metal facilities con-

structed at KIT.

Both THEADES (LBE) and KASOLA (Na) facilities are large-scale thermo-

hydraulic loops for testing components at prototypical scale. The main components

mentioned in the previous sections, for example, sump tank, pump, heat exchangers,

and cover gas system, can be observed. In principle, the arrangement is similar for

LBE and sodium, although it is worth noting that the first one (see Fig. 3.3.5) includes

an oxygen control system and the second one (see Fig. 3.3.6), a cold trap.

These loops are constructed with vertical test ports, where different experimental

sections with upward flow can be installed. Some representative test sections studied

in these ports are presented in the next section. The main parameters of these facilities

are listed in Table 3.3.1.

The fluid temperature range is selected with sufficient margin to freezing (consid-

ering that local cold spots might exist) on the lower end and to excessive corrosion on

the upper end. Both considerations lead to a narrower range in LBE than in sodium.

An electromagnetic annular linear induction pump (ALIP) is placed near the bot-

tom in KASOLA and pushes the sodium upward. On the other hand, a centrifugal

pump is placed near the top in THEADES and pushes the LBE downward. The

different arrangement is related to the pump characteristics discussed earlier.

MYRRHA

target II

Pump Test port Cover gas system

Expansion motor

tank

PbBi air-

cooler

Flow direction

Pump

Oxygen

Fill and drain control LBE rod

lines system

bundle

experiment Heater unit

PbBi air-

cooler

Test port

Flow direction Test port Test port

Sump

tank

Fig. 3.3.5 THEADES (LBE) facility at KIT: Thermal hydraulics and ADS design.