Page 71 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 71

46 Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

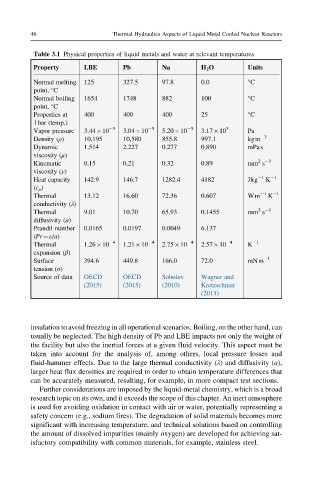

Table 3.1 Physical properties of liquid metals and water at relevant temperatures

Property LBE Pb Na H 2 O Units

Normal melting 125 327.5 97.8 0.0 °C

point, °C

Normal boiling 1654 1748 882 100 °C

point, °C

Properties at 400 400 400 25 °C

1bar (temp.)

Vapor pressure 3.44 10 5 3.04 10 5 5.20 10 5 3.17 10 3 Pa

Density (ρ) 10,195 10,580 855.8 997.1 kgm 3

Dynamic 1.514 2.227 0.277 0.890 mPas

viscosity (μ)

2 1

Kinematic 0.15 0.21 0.32 0.89 mm s

viscosity (ν)

Heat capacity 142.9 146.7 1282.4 4182 Jkg 1 K 1

(c p )

Thermal 13.12 16.60 72.36 0.607 Wm 1 K 1

conductivity (λ)

2 1

Thermal 9.01 10.70 65.93 0.1455 mm s

diffusivity (a)

Prandtl number 0.0165 0.0197 0.0049 6.137 –

(Pr¼ν/a)

Thermal 1.26 10 4 1.21 10 4 2.75 10 4 2.57 10 4 K 1

expansion (β)

Surface 394.6 449.8 166.0 72.0 mNm 1

tension (σ)

Source of data OECD OECD Sobolev Wagner and

(2015) (2015) (2010) Kretzschmar

(2013)

insulation to avoid freezing in all operational scenarios. Boiling, on the other hand, can

usually be neglected. The high density of Pb and LBE impacts not only the weight of

the facility but also the inertial forces at a given fluid velocity. This aspect must be

taken into account for the analysis of, among others, local pressure losses and

fluid-hammer effects. Due to the large thermal conductivity (λ) and diffusivity (a),

larger heat flux densities are required in order to obtain temperature differences that

can be accurately measured, resulting, for example, in more compact test sections.

Further considerations are imposed by the liquid-metal chemistry, which is a broad

research topic on its own, and it exceeds the scope of this chapter. An inert atmosphere

is used for avoiding oxidation in contact with air or water, potentially representing a

safety concern (e.g., sodium fires). The degradation of solid materials becomes more

significant with increasing temperature, and technical solutions based on controlling

the amount of dissolved impurities (mainly oxygen) are developed for achieving sat-

isfactory compatibility with common materials, for example, stainless steel.