Page 89 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 89

64 Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

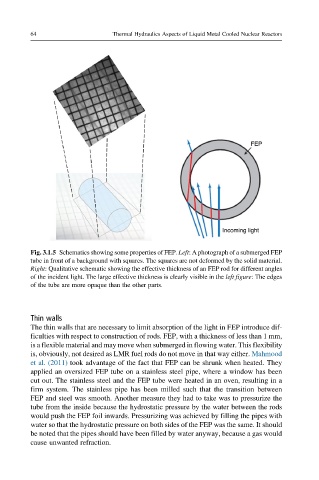

Fig. 3.1.5 Schematics showing some properties of FEP. Left: A photograph of a submerged FEP

tube in front of a background with squares. The squares are not deformed by the solid material.

Right: Qualitative schematic showing the effective thickness of an FEP rod for different angles

of the incident light. The large effective thickness is clearly visible in the left figure: The edges

of the tube are more opaque than the other parts.

Thin walls

The thin walls that are necessary to limit absorption of the light in FEP introduce dif-

ficulties with respect to construction of rods. FEP, with a thickness of less than 1 mm,

is a flexible material and may move when submerged in flowing water. This flexibility

is, obviously, not desired as LMR fuel rods do not move in that way either. Mahmood

et al. (2011) took advantage of the fact that FEP can be shrunk when heated. They

applied an oversized FEP tube on a stainless steel pipe, where a window has been

cut out. The stainless steel and the FEP tube were heated in an oven, resulting in a

firm system. The stainless pipe has been milled such that the transition between

FEP and steel was smooth. Another measure they had to take was to pressurize the

tube from the inside because the hydrostatic pressure by the water between the rods

would push the FEP foil inwards. Pressurizing was achieved by filling the pipes with

water so that the hydrostatic pressure on both sides of the FEP was the same. It should

be noted that the pipes should have been filled by water anyway, because a gas would

cause unwanted refraction.