Page 298 - Trenchless Technology Piping Installation and Inspection

P. 298

262 Cha pte r S i x

FIGURE 6.16 Insert a tee fi ttings for sewer lateral connections. (Source:

Handbook of Polyethylene Pipe, 2008.)

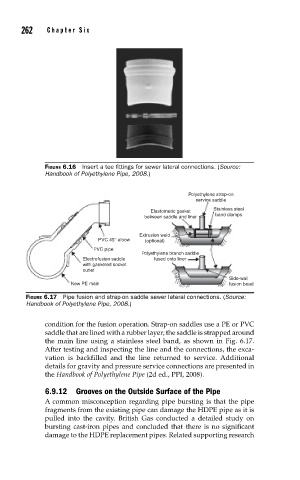

Polyethylene strap-on

service saddle

Stainless steel

Elastomeric gasket

between saddle and liner band clamps

Extrusion weld

PVC 45° elbow (optional)

PVC pipe

Polyethylene branch saddle

Electrofusion saddle fused onto liner

with gasketed socket

outlet

Side-wall

New PE main fusion bead

FIGURE 6.17 Pipe fusion and strap-on saddle sewer lateral connections. (Source:

Handbook of Polyethylene Pipe, 2008.)

condition for the fusion operation. Strap-on saddles use a PE or PVC

saddle that are lined with a rubber layer; the saddle is strapped around

the main line using a stainless steel band, as shown in Fig. 6.17.

After testing and inspecting the line and the connections, the exca-

vation is backfilled and the line returned to service. Additional

details for gravity and pressure service connections are presented in

the Handbook of Polyethylene Pipe (2d ed., PPI, 2008).

6.9.12 Grooves on the Outside Surface of the Pipe

A common misconception regarding pipe bursting is that the pipe

fragments from the existing pipe can damage the HDPE pipe as it is

pulled into the cavity. British Gas conducted a detailed study on

bursting cast-iron pipes and concluded that there is no significant

damage to the HDPE replacement pipes. Related supporting research