Page 30 - Trenchless Technology Piping Installation and Inspection

P. 30

New Pipeline Installations 5

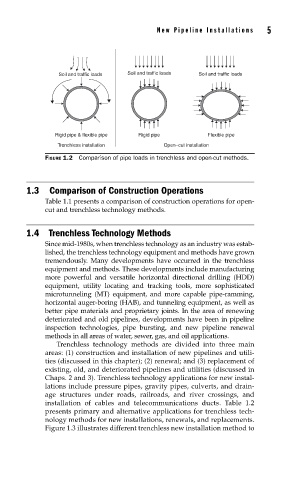

Soil and traffic loads Soil and traffic loads Soil and traffic loads

Rigid pipe & flexible pipe Rigid pipe Flexible pipe

Trenchless installation Open–cut installation

FIGURE 1.2 Comparison of pipe loads in trenchless and open-cut methods.

1.3 Comparison of Construction Operations

Table 1.1 presents a comparison of construction operations for open-

cut and trenchless technology methods.

1.4 Trenchless Technology Methods

Since mid-1980s, when trenchless technology as an industry was estab-

lished, the trenchless technology equipment and methods have grown

tremendously. Many developments have occurred in the trenchless

equipment and methods. These developments include manufacturing

more powerful and versatile horizontal directional drilling (HDD)

equipment, utility locating and tracking tools, more sophisticated

microtunneling (MT) equipment, and more capable pipe-ramming,

horizontal auger-boring (HAB), and tunneling equipment, as well as

better pipe materials and proprietary joints. In the area of renewing

deteriorated and old pipelines, developments have been in pipeline

inspection technologies, pipe bursting, and new pipeline renewal

methods in all areas of water, sewer, gas, and oil applications.

Trenchless technology methods are divided into three main

areas: (1) construction and installation of new pipelines and utili-

ties (discussed in this chapter); (2) renewal; and (3) replacement of

existing, old, and deteriorated pipelines and utilities (discussed in

Chaps. 2 and 3). Trenchless technology applications for new instal-

lations include pressure pipes, gravity pipes, culverts, and drain-

age structures under roads, railroads, and river crossings, and

installation of cables and telecommunications ducts. Table 1.2

presents primary and alternative applications for trenchless tech-

nology methods for new installations, renewals, and replacements.

Figure 1.3 illustrates different trenchless new installation method to