Page 407 - Trenchless Technology Piping Installation and Inspection

P. 407

Inspection and QA/QC for Trenchless Installation and Replacement Methods 357

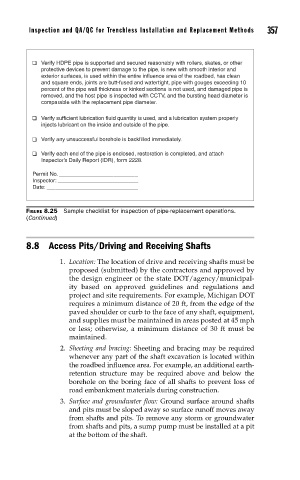

Verify HDPE pipe is supported and secured reasonably with rollers, skates, or other

protective devices to prevent damage to the pipe, is new with smooth interior and

exterior surfaces, is used within the entire influence area of the roadbed, has clean

and square ends, joints are butt-fused and watertight, pipe with gouges exceeding 10

percent of the pipe wall thickness or kinked sections is not used, and damaged pipe is

removed, and the host pipe is inspected with CCTV, and the bursting head diameter is

comparable with the replacement pipe diameter.

Verify sufficient lubrication fluid quantity is used, and a lubrication system properly

injects lubricant on the inside and outside of the pipe.

Verify any unsuccessful borehole is backfilled immediately.

Verify each end of the pipe is enclosed, restoration is completed, and attach

Inspector’s Daily Report (IDR), form 2228.

Permit No. __________________________

Inspector: ___________________________

Date: _______________________________

FIGURE 8.25 Sample checklist for inspection of pipe-replacement operations.

(Continued)

8.8 Access Pits/Driving and Receiving Shafts

1. Location: The location of drive and receiving shafts must be

proposed (submitted) by the contractors and approved by

the design engineer or the state DOT/agency/municipal-

ity based on approved guidelines and regulations and

project and site requirements. For example, Michigan DOT

requires a minimum distance of 20 ft, from the edge of the

paved shoulder or curb to the face of any shaft, equipment,

and supplies must be maintained in areas posted at 45 mph

or less; otherwise, a minimum distance of 30 ft must be

maintained.

2. Sheeting and bracing: Sheeting and bracing may be required

whenever any part of the shaft excavation is located within

the roadbed influence area. For example, an additional earth-

retention structure may be required above and below the

borehole on the boring face of all shafts to prevent loss of

road embankment materials during construction.

3. Surface and groundwater flow: Ground surface around shafts

and pits must be sloped away so surface runoff moves away

from shafts and pits. To remove any storm or groundwater

from shafts and pits, a sump pump must be installed at a pit

at the bottom of the shaft.