Page 61 - Trenchless Technology Piping Installation and Inspection

P. 61

New Pipeline Installations 33

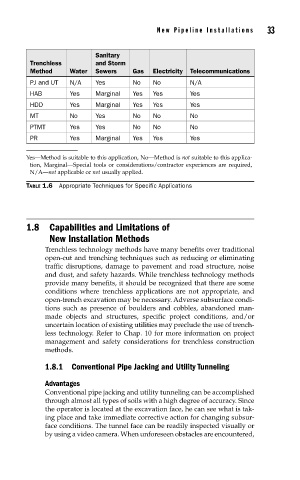

Sanitary

Trenchless and Storm

Method Water Sewers Gas Electricity Telecommunications

PJ and UT N/A Yes No No N/A

HAB Yes Marginal Yes Yes Yes

HDD Yes Marginal Yes Yes Yes

MT No Yes No No No

PTMT Yes Yes No No No

PR Yes Marginal Yes Yes Yes

Yes—Method is suitable to this application, No—Method is not suitable to this applica-

tion, Marginal—Special tools or considerations/contractor experiences are required,

N/A—not applicable or not usually applied.

TABLE 1.6 Appropriate Techniques for Specific Applications

1.8 Capabilities and Limitations of

New Installation Methods

Trenchless technology methods have many benefits over traditional

open-cut and trenching techniques such as reducing or eliminating

traffic disruptions, damage to pavement and road structure, noise

and dust, and safety hazards. While trenchless technology methods

provide many benefits, it should be recognized that there are some

conditions where trenchless applications are not appropriate, and

open-trench excavation may be necessary. Adverse subsurface condi-

tions such as presence of boulders and cobbles, abandoned man-

made objects and structures, specific project conditions, and/or

uncertain location of existing utilities may preclude the use of trench-

less technology. Refer to Chap. 10 for more information on project

management and safety considerations for trenchless construction

methods.

1.8.1 Conventional Pipe Jacking and Utility Tunneling

Advantages

Conventional pipe jacking and utility tunneling can be accomplished

through almost all types of soils with a high degree of accuracy. Since

the operator is located at the excavation face, he can see what is tak-

ing place and take immediate corrective action for changing subsur-

face conditions. The tunnel face can be readily inspected visually or

by using a video camera. When unforeseen obstacles are encountered,