Page 91 - Trenchless Technology Piping Installation and Inspection

P. 91

58 Cha pte r T w o

FIGURE 2.5 CIPP installation process. (Source: Insituform Technologies.)

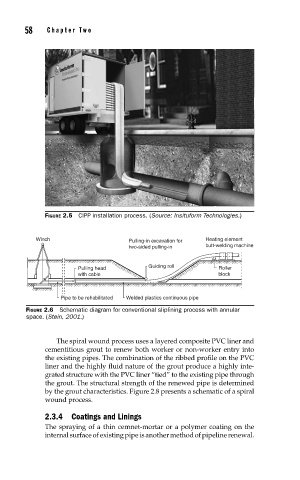

Winch Pulling-in excavation for Heating element

two-sided pulling-in butt-welding machine

Guiding roll

Pulling head Roller

with cable block

Pipe to be rehabilitated Welded plastics continuous pipe

FIGURE 2.6 Schematic diagram for conventional sliplining process with annular

space. (Stein, 2001.)

The spiral wound process uses a layered composite PVC liner and

cementitious grout to renew both worker or non-worker entry into

the existing pipes. The combination of the ribbed profile on the PVC

liner and the highly fluid nature of the grout produce a highly inte-

grated structure with the PVC liner “tied” to the existing pipe through

the grout. The structural strength of the renewed pipe is determined

by the grout characteristics. Figure 2.8 presents a schematic of a spiral

wound process.

2.3.4 Coatings and Linings

The spraying of a thin cemnet-mortar or a polymer coating on the

internal surface of existing pipe is another method of pipeline renewal.