Page 242 - Tribology in Machine Design

P. 242

Sliding-element bearings 227

categories of self-lubricating bearings can be distinguished and within each

category further subcategories can easily be identified.

A. Homogeneous metal composites

These are porous, sintered-metal bearings. The majority of them are

iron-bronzes, but occasionally lead-bronze, lead-irons or aluminiums are

used. The softer alloys resist galling longest if the lubricant film breaks

down, while the aluminiums can carry nearly twice the compressive load.

A-l. Liquid-impregnated bearings are soaked in oil (often ordinary

machine oil), which may make up 30 per cent of the finished bearing's

volume. In operation, frictional heat and capillary action draw the oil from

the pores to lubricate the shaft or thrust collar. High temperatures and high

speeds can deplete the oil quickly. They are not recommended for operation

in a dusty environment because the oil film can trap grit. Surface finish of

the mating surfaces should be 0.2/^m or better.

A-2. Solid-impregnated bearings are typically sintered from a blend of

powdered graphite and iron-bronze. They are particularly useful with shaft

finishes of 0.4 to 0.8 /im.

B. Metal-backed laminates

Good lubricating materials usually lack structural strength. These lami-

nates consist of a steel backbone on top of which a thin layer of lubricating

material is deposited and hence they can withstand greatly increased

permissible contact stresses. The lubricant layers may consist of:

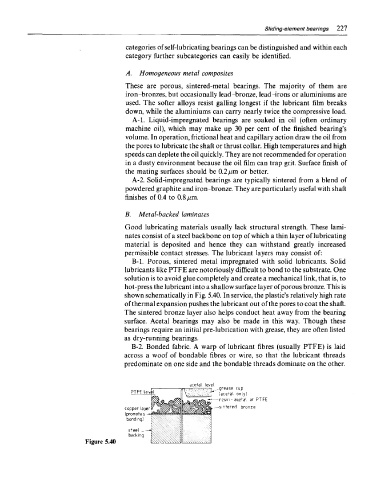

B-l. Porous, sintered metal impregnated with solid lubricants. Solid

lubricants like PTFE are notoriously difficult to bond to the substrate. One

solution is to avoid glue completely and create a mechanical link, that is, to

hot-press the lubricant into a shallow surface layer of porous bronze. This is

shown schematically in Fig. 5.40. In service, the plastic's relatively high rate

of thermal expansion pushes the lubricant out of the pores to coat the shaft.

The sintered bronze layer also helps conduct heat away from the bearing

surface. Acetal bearings may also be made in this way. Though these

bearings require an initial pre-lubrication with grease, they are often listed

as dry-running bearings.

B-2. Bonded fabric. A warp of lubricant fibres (usually PTFE) is laid

across a woof of bondable fibres or wire, so that the lubricant threads

predominate on one side and the bondable threads dominate on the other.

Figure 5.40