Page 241 - Tribology in Machine Design

P. 241

226 Tribology in machine design

contact at this point. Should this occur the damage to the white metal, being

a great deal deeper than between the normal steel and cast-iron, allows the

fluid pressure in the cavity to fall, thus still further reducing the safety of the

bearing.

5.11. Self-lubricating Although self-lubricating bearings account for only a small fraction of the

bearings world's total bearing usage, they are now firmly established in certain

applications. Two classes of self-lubricating material widely used in general

engineering applications are plastics and metals containing solid lubricant

fillers. Self-lubricating materials are most useful either as dry bearings or as

bearings in marginally lubricated applications.

Bearings based on thermosetting resins first appeared on the market in

the 1930s. The thermoplastics came later, with nylon first on the scene in

bearing applications, followed by PTFE in the early 1950s and more recently

by the polyacetals. The economic grounds for preferring plastic are, at best,

not very strong, and it is on the grounds of performance that their main

claim must be made. The most important property of the bearing plastics,

particularly thermoplastics, is their compatibility with metals, and in

particular with the steel against which they have to run. There is an air of

contradiction about self-lubricating bearings. They must wear to fight

wear; they depend on friction to overcome friction. The precise mechanisms

of their operation vary and depend on the particular material being used.

There are, however, similar elements in the basic mechanisms. The contact

between the bearing and its mating surface generates a lubricating film. The

film may be composed of solids transferred from the bearing surface; or

frictional heat and capillary action may draw a lubricant out of a porous

matrix. These two processes may be at work at the same time. Most self-

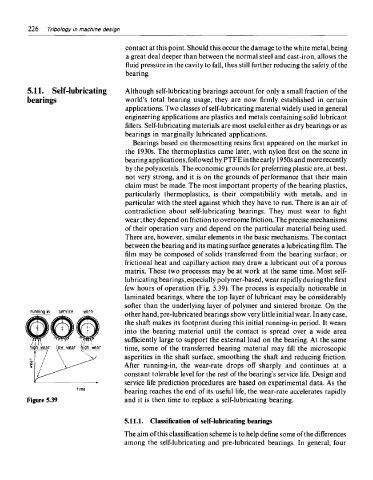

lubricating bearings, especially polymer-based, wear rapidly during the first

few hours of operation (Fig. 5.39). The process is especially noticeable in

laminated bearings, where the top layer of lubricant may be considerably

softer than the underlying layer of polymer and sintered bronze. On the

other hand, pre-lubricated bearings show very little initial wear. In any case,

the shaft makes its footprint during this initial running-in period. It wears

into the bearing material until the contact is spread over a wide area

sufficiently large to support the external load on the bearing. At the same

time, some of the transferred bearing material may fill the microscopic

asperities in the shaft surface, smoothing the shaft and reducing friction.

After running-in, the wear-rate drops off sharply and continues at a

constant tolerable level for the rest of the bearing's service life. Design and

service life prediction procedures are based on experimental data. As the

bearing reaches the end of its useful life, the wear-rate accelerates rapidly

Figure 5.39 and it is then time to replace a self-lubricating bearing.

5.11.1. Classification of self-lubricating bearings

The aim of this classification scheme is to help define some of the differences

among the self-lubricating and pre-lubricated bearings. In general, four