Page 278 - Tribology in Machine Design

P. 278

Rolling-contact bearings 263

nozzle size. Jet velocity in turn has a significant effect on the bearing

temperature. With proper bearing and cage design, placement of nozzles

and jet velocities, jet lubrication can be successfully used for small bore

6

ball-bearings with speeds of up to 3.0 x 10 DN. Likewise for large bore ball-

6

bearings, speeds to 2.5 x 10 DN are attainable.

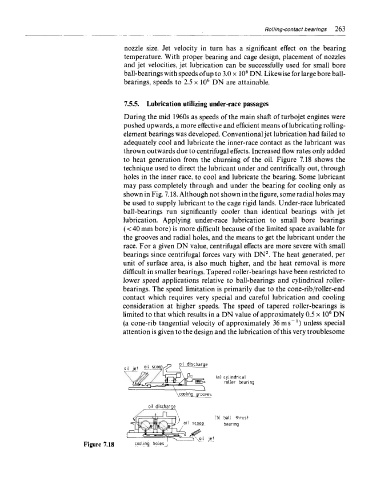

7.5.5. Lubrication utilizing under-race passages

During the mid 1960s as speeds of the main shaft of turbojet engines were

pushed upwards, a more effective and efficient means of lubricating rolling-

element bearings was developed. Conventional jet lubrication had failed to

adequately cool and lubricate the inner-race contact as the lubricant was

thrown outwards due to centrifugal effects. Increased flow rates only added

to heat generation from the churning of the oil. Figure 7.18 shows the

technique used to direct the lubricant under and centrifically out, through

holes in the inner race, to cool and lubricate the bearing. Some lubricant

may pass completely through and under the bearing for cooling only as

shown in Fig. 7.18. Although not shown in the figure, some radial holes may

be used to supply lubricant to the cage rigid lands. Under-race lubricated

ball-bearings run significantly cooler than identical bearings with jet

lubrication. Applying under-race lubrication to small bore bearings

(<40mm bore) is more difficult because of the limited space available for

the grooves and radial holes, and the means to get the lubricant under the

race. For a given DN value, centrifugal effects are more severe with small

2

bearings since centrifugal forces vary with DN . The heat generated, per

unit of surface area, is also much higher, and the heat removal is more

difficult in smaller bearings. Tapered roller-bearings have been restricted to

lower speed applications relative to ball-bearings and cylindrical roller-

bearings. The speed limitation is primarily due to the cone-rib/roller-end

contact which requires very special and careful lubrication and cooling

consideration at higher speeds. The speed of tapered roller-bearings is

6

limited to that which results in a DN value of approximately 0.5 x 10 DN

1

(a cone-rib tangential velocity of approximately 36ms" ) unless special

attention is given to the design and the lubrication of this very troublesome

Figure 7.18